Steering System: Types, Function & Components

What is Steering System?

Steering System: Types, Function & Components :- It is found that the perfect handling of a car makes your journey safe and over whelmed, this is why a steering is introduced in the automobile industry. The smoother touch of the wheel must be directly with the steering system in order to make it more effortless and precise. Other than this the suspension also plays a very vital role in an automobile industry. It takes a very high quality steering system and steering parts to achieve an excellent handling. Scroll down to know more about the steering system and all about it.

The Function Of A Steering System

Once the rotation of the steering wheel takes place, the vehicle responds to this system. A Steering system is responsible for giving a quite smooth route which includes a group of parts which is referred to as the steering system which transmits the movement of the steering wheel down the steering shaft in order to move the wheel either left or right.

Popular Rack and Pinion Steering System

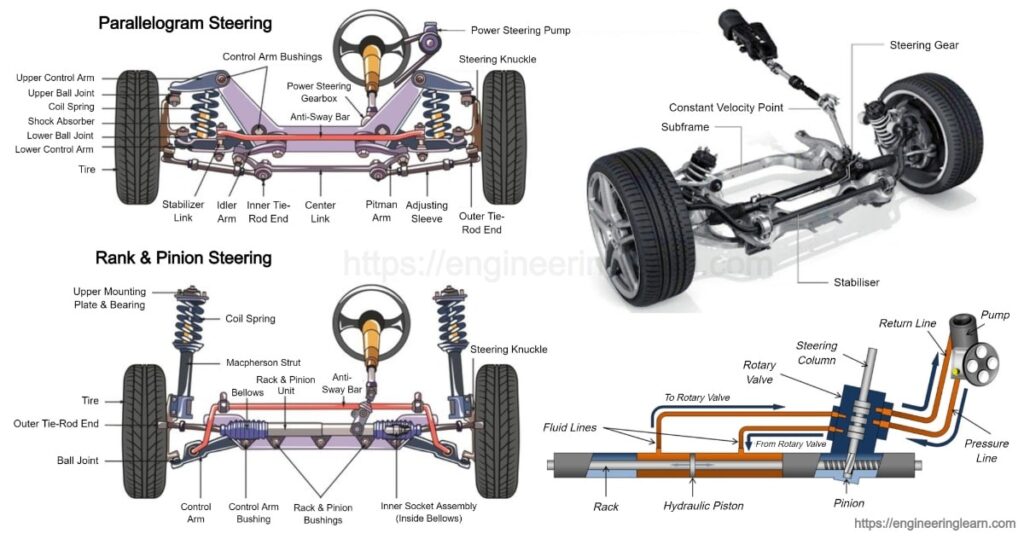

In most of the cars and SUVs on today’s road consists of a rack and pinion steering system. This system is responsible for converting the rotational motion of the steering wheel into the linear motion which turns the wheels and guides the path. This system involves a circular gear which locks the teeth on a bar. This transforms the big rotations of the steering wheel into small, accurate turns of the wheels which gives a solid and direct feel to the steering.

Effects of Power Steering at the Rack and Pinion

The latest cars and the trucks are found having a power steering system function which is also referred to as power-assisted steering. This is used to give the extra energy in order to help in turning the wheels and means parking which requires quite less effort as compared to simple manual force. In comparison to power steering the rack and pinion steering system is quite different as it adds the engine-driven pump or electric motor to aid the steering assembly.

The system helps in having a higher gear steering which means that you have to turn the steering wheel with less in order to turn the wheels further. Therefore, it has a sharpened up response time which makes the steering even more precise. In such busy roads and traffic jams, the means drivers can more safely maneuver in close proximity to the other vehicles. Keeping the tight control at varying speeds, at any condition in the critical situations which helps to avoid accidents.

Components of Steering System in Car

All the racks and pinions are one of the most essential parts that are mostly constructed by MOOG and also includes the axial rods, tie rod ends, drag links, wheel end bearings. These are the steering parts which are robust and hard wearing that enough to provide both strength and durability. Select the parts that meets the specifications of a manufacturer means that the whole assembly will be responsive as well as long-lasting.

1. Return of four-wheel steering

Beneath the swivel of the front wheels there is a steering system of some cars which affects all the four. This has been exclusively found in the sporty and luxury models where there is an increasing trend towards the feature in more affordable cars.

A four-wheel steering control unit is set up behind the rear axle of the car which affects the rear wheels as per the requirement. The wheels of the car are found turning in an opposite direction at a comparatively lower speed, whereas turning all the four wheels in concert helps in maintaining the stability and prevents fishtailing.

Having a technical four-wheel steering refers to as better handling, as the steering is monitored only in the emergency situations wherein the car is found reacting with the optimum response. This type of steering system appears in the brands like Renaults, Honda, Nissan and Mazda etc. in order to give new drivers new heights of drivability and responsiveness and keep us safer on the roads.

2. Steering box

At the bottom of the steering column there is a worm gear which is fit inside the box. A worm is a threaded cylinder which is similar to a short bolt that turns a bolt which holds a nut on it. After this the nut is found moving along the bolt. Similarly, turning the worm moves anything which is fitted inside its thread.

Power Assisted Steering

In case of a heavy car, either the steering is too heavy or it is inconveniently geared low, so that the steering wheel can require many turns from locks to locks. Heavy gearing can sometimes be quite troublesome while the parking is in confined spaces whereas the power-assisted steering system can overcome such problems. The engine drives the pump which supplies the oil under a very high pressure to the rack or the steering box.

The valves in the steering rack or box gets opened whenever the driver turns the wheel which allows the oil to enter into the cylinder. The oil works as a piston which helps to push the steering in the required direction. Once the driver stops turning the wheel, the valve gets closed and the pushing action of the piston gets stopped. The power is helpful in assisting the steering and the wheel which is still linked to the road wheels in a usual way.

Working of Steering System

Once the steering wheel is rotated the shaft attached to it also rotates along with it. This results in rotating the pinion which is placed on the top of the rack. The rotation of the pinion lets the rack move linearly also moving the tie rod.

Once the tie rod is connected to the steering arm it lets the wheel turn. The size of the pinion is responsible and has an effect on its turning. In case the pinion is large in size it means that you shall be getting more number of turns from the less steering wheel rotation that makes it harder to control.

Whereas, on the other hand a small pinion refers to as that which means that it will be easier to control what is required to multiple the steering wheel that turns to make the car corner.

This is how the Rack and Pinion System works efficiently. However, it is a quite simple device which can be used multiple times and as an advanced system which can make it even better to use.

Recirculating Ball Steering System

This system is known with multiple names like worm & sector and recirculating ball & nut. This steering system is most commonly found in old cars and the heavy-duty vehicles like trucks. This working is quite different from the rack and pinion.

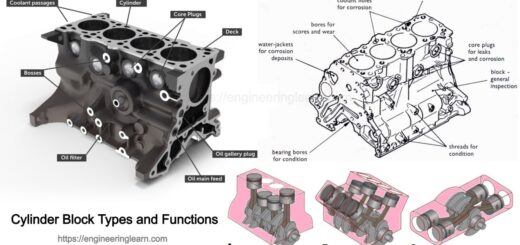

Construction of Steering System

The ball steering system which recirculates has two different gears, one is the worm gear and the other is sector gear. The steering wheel is connected via a shaft which is threaded and is then connected to the block. The worm gear is the one which is quite big and undergoes the block which is threaded in such a way it allows the worm gear inside. This block has gear teeth at the outer side which is connected to the sector gear. The sector gear is kept connected to the pitman arm which is further attached to the tie rod. The working is also quite simple as that like a rack and pinion.

Power Steering System

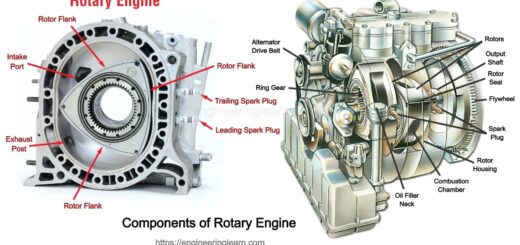

The power steering is added with some more parts and components to the rack and pinion system which makes it simplified and easy to use. In most of the cases the pump, pressure tubes, rotary control valve, fluid lines and a hydraulic piston are the common parts of a power steering system.

The main work of the pump is to, pump the fluid around the place where it is required. The rotary control valve is the valve which ensures that the movement of fluid is only performed once the driver is actually steering the car. The hydraulic piston keeps moving, depending upon the fluid line which brings the high-pressure fluid. This movement of the piston on the rack makes it easier for the driver as it usually applies force that is necessary to steer the car.

Speed Sensitive Steering

A power steering system is commonly referred to as a speed sensitive steering, wherein the steering is heavily assisted at a very low speed and is assisted lightly in the case of a high speed. The auto makers have a conceptions that there should be a need to make large steering inputs while maneuvering for parking whereas it is not mandatory in case the travel speed is high.

The latest speed-sensitive power steering systems is responsible for reducing the mechanical or electrical assistance as the speed of the vehicle increases which gives it a more direct feel. This is the reason why this feature is gradually becoming more common these days.

Parts of Steering System

1. General System Function

In a contemporary power steering system, the pump is used to provide power steering fluid under pressure to the rack and the pinion unit. Whenever the driver provides steering input by turning the steering wheel, the power steering control valve undergoes fluid pressure to one side of a piston, which helps the driver in turning the wheel.

2. Power Steering Pump

The power steering pump is used to turn the accessory drive belt or serpentine belt in order to develop the fluid pressure in the higher side of the power steering hose so that the input side of the power steering can control the valve.

3. Steering Coupler

It is referred to as a which allows the steering wheel to rotate without binding up with the column, because of the fact that the input shaft and the steering column are not found to be in a perfect alignment instead are at a slight angle to each other.

4. Tie Rod Ends

This is a component which is attach at the steering rack’s end where the steering knuckles and allows the motion of the rack to be translated into turning the movement of the front wheels. These are the parts which rotate horizontally for steering the input translation and the pivot vertically as well as diagonally once the vehicle encounters a roughness in the road and the wheels get bounced.

5. Power Steering Hoses

It is important to know that there are two main power steering hoses, one is the high side and other is the lower side. Both the hoses are found being attached to the rack and pinion with the help of a threaded brass fitting. The high side hose is attached to the power steering pump using a threaded brass fitting whereas the low side hose slides are a small pipe which is securely placed with a hose clamp.

The high side hose carries a power steering fluid under the pressure of the rack which is provided with the power assist to the steering inputs whereas the lower side hose is responsible for carrying a low pressure fluid back to the pump.

Types of Steering System

There are three types of steering system which are as follows:

1. Bicycle Steering

These type of steering systems are rarely fixed whereas the front wheel is steered. It is essential to install these for a safe turning and so the two wheels must roll about a point.

2. Turntable Steering Or Centre Pivot Steering

Once the front wheels are turned, then the whole front axle is turned about the central pivot. In this case, the perpendicular of all the wheels meet at a particular point during the turning. Therefore, the turning is safe and the wheels roll quite freely.

3. Ackerman Steering or Side Pivot Steering

Mostly the front axle is pivoted on the either side of the axle as the wheels are mounted on the stub axles. This is why the stub axles are turned by the steering arms and are connected to the tie rod.

Image Source :- 123rf, dsauto, autointhebox