Fuel Gauge Working and Types

Types of fuel gauges

What is a fuel gauge?

Fuel gauge is a device which indicates the amount of fuel in a tank of vehicle. In Electrical Engineering, the term fuel gauge is used to represent a device which calculates the amount of charge in the accumulators. It is fixed on the dashboard of the vehicle. Fuel gauge shows reading in analog sticks or digital bars.

Need of a fuel gauge?

Sudden shortage of fuel in the vehicle running fast on highways, hundreds of vehicle moving in busy roads of cities, air transportation, and military aircraft serving in fights at the borders can cause various problems like aircraft crashes, major accidents and traffic jams resulting into loss of time, human resources and equipments. Thus, there the need of a device called fuel gauge which sought to solve all such problems by determining the level of fuel in tank.

History of fuel gauges:

Before the invention of the fuel gauge, in the early 90’s, the drivers used to determine the level of fuel in the tank with the help of rulers marked with centimeters and inches. But those rules were only provided with the employees working at the fuel station.

In 1917 John Collison came up with the idea of gas fuel gauge and represented it to General Motors Co. in 1920 .Now a days, various types of fuel gauges are present in the market depending on the size of the vehicle, number of fuel tank, principle of working or accuracy of the fuel gauge.

Working principle of fuel gauge:

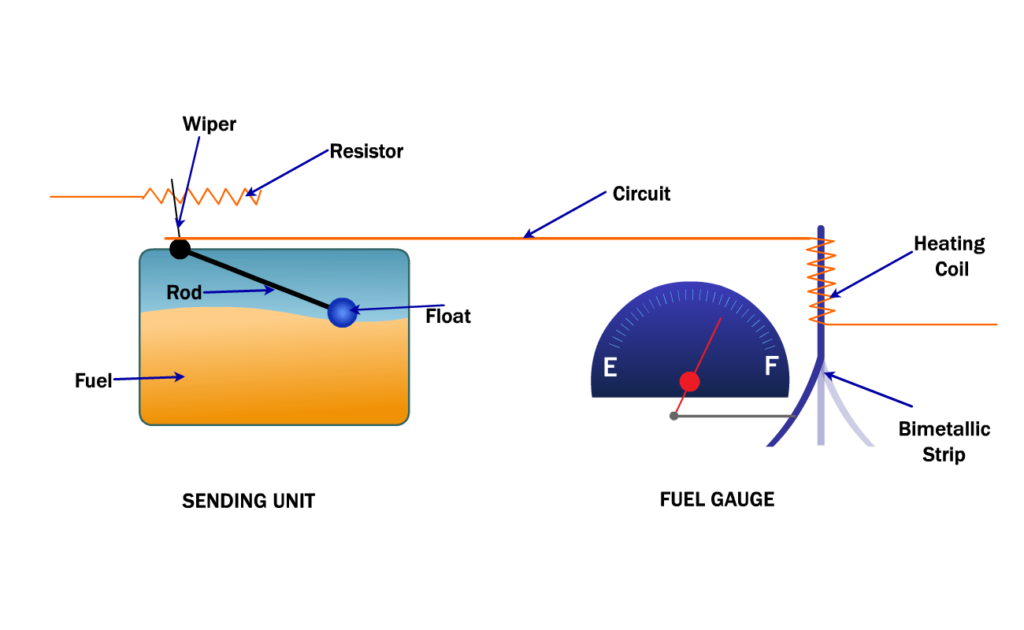

Fuel gauges consists of two parts, one of which is fixed the tank called sender part while the other part fixed on the dashboards of the vehicle called receiver part. The sender part send signal using float arm, or rheostat, bimetal strip or various arrangements and the receiver part shows the amount of fuel in the form of analog sticks or digital bars by understanding those signals.

Types of fuel gauges:

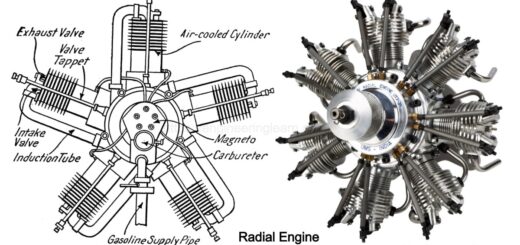

From the various fuel gauges available, the one which is to be installed in a particular type of automobile depends on its size and number of tanks in that automobile. For example: automobiles like airplane and aircraft where tanks are made at very large distance from the cockpit, mechanical fuel gauges can’t be used. At this much distance use mechanical fuel gauge is practically not possible and they can’t be expected to give accurate readings. That is why in such cases electrical or electronic fuel gauges are used.

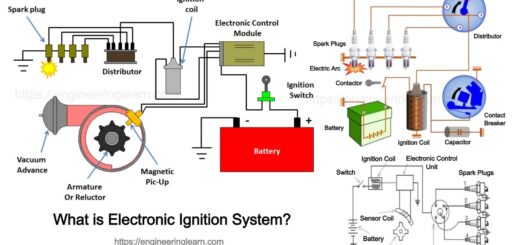

1. Electrical fuel gauges:

As the name suggests, in this type of fuel gauges either the sent signal is electrical or the sending part uses electricity from the battery of the vehicle to send signal. These types of gauges are the most accurate ones.

Electrical gauges are further divided into four sub-categories:

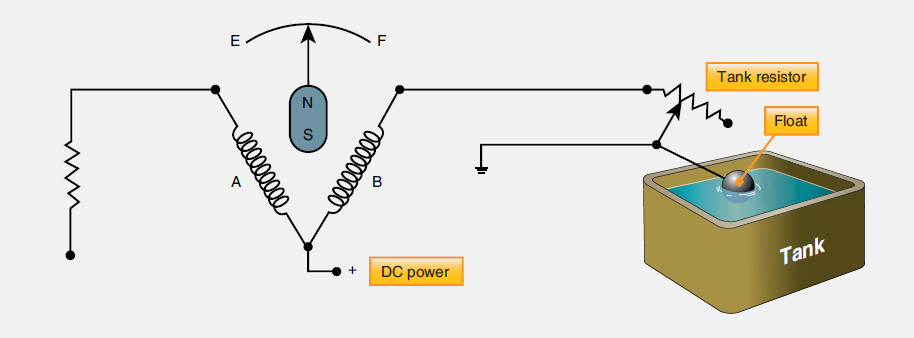

(A) Electrical fuel gauge with balanced coils–

It consists of two parts one fixed on the tank and other part is fixed on dashboard. Both the parts are connected through a single wire. The part fixed in the tank consists of a rheostat and a float. The resistance in the rheostat changes as the positions of the float changes in the tank. The other part fixed on the tank consists of two coils, 90 degree apart with an armature and pointer provided at the intersection of the coil axis. On Switching on the ignition the current flows through the coils producing a magnetic field acting on the armature to which pointer is connected.

The resistance in the rheostat is highest when fuel gauge shows that tank is full and the resistance is lowest when tank is empty.

(B) Bimetal type electric fuel gauge–

Like other gauges it also consists of two parts .First is the sender part which is fixed outside the tank and the other part is the receiver part which shows the reading. The two parts are connected through a single wire.

It is made up of heating wire wound around a bimetal strip which is basically a strip used to show temperature change through mechanical displacement. It works on the principle of external float system. As the position of the float changes the height of earthed contact also changes which In turn changes the tension in the bimetal strip. The whole working unit works on the current received from the battery.

When the ignition is on, the current flows through the working part and the heat is generated causing the bimetal strip to bend.

- Condition1-When the tank is empty, there is just a point contact between the two sender part .As the bimetal strip bends, the contact opens and the circuit breaks. The heating coil of the sender and receiver part is made to join in series thus same bending occurs in the bimetal strip of the receiving part, which pulls the pointer to empty.

- Condition 2-The float rests on the surface of the fuel. So when the tank is full, the float and earthed contact raises up, bending the bimetal strip. As the more current is withdrawn to heat the bimetal strip under tension. Same bending of bimetal strip occurs in the receiving part which pulls the pointer to full.

(C) Thermal type electric fuel gauge

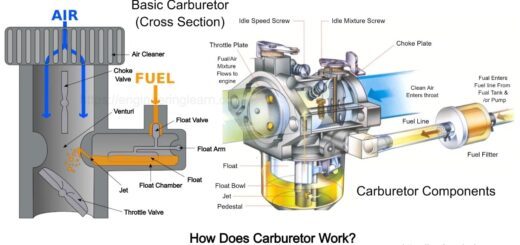

The common part of bimetal and thermal electrical gauge is that the construction of both the receiving part is same. In this type of electric gauge, the rheostat is present in a form of sliding contact on a resistance wire which is regulated by float. The two contacts are connected in series to a voltage supply which works when ignition starts.

In this gauge, the resistance is lowest when the tank is full and highest when the tank is empty, unlike the gauge with balanced coils.

When the resistance is least in the rheostat, of the part fixed in tank, the current flows through the circuit causing the bimetal strip to bend fully.

When the resistance is highest, it reduces the current flow to the circuit indicating that tank is empty.

(D) Thermostatic type electric fuel gauge

This type of gauge was used in old models of car. The sender part and the receiver part are connected by two wires. Pair thermostat plates are used in the receiver part, wound by a heating coil. This also works on the current provided by the battery when the ignition Is switched on. The current passes through the coil causing thermostat plates to bend due to heat to move the indicator over the scale.

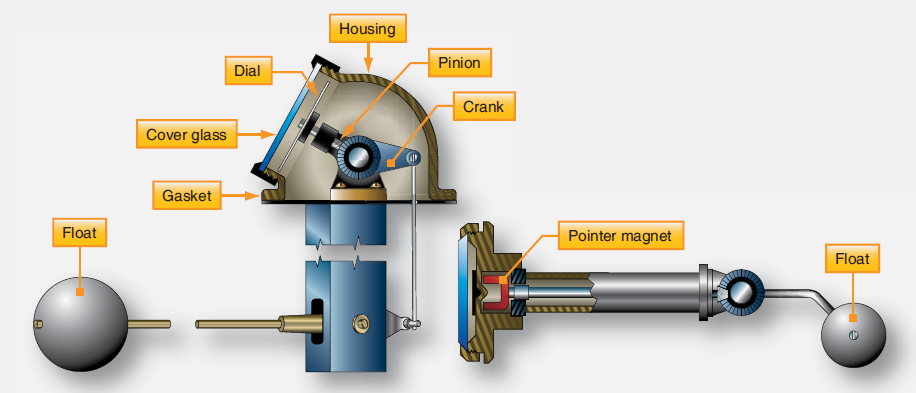

2. Mechanical type fuel gauge

They work on the internal float mechanism and are also known as a direct reading gauge. The float rests on the surface of the fuel to which the indicator is connected. The float mechanically controls the indicator. As the height of the fuel changes, the level of floats also changes, thus changing the reading shown on the dashboard.

3. The electronic type fuel gauge

Unlike the types of fuel gauge we discussed above, It has no moving part like float ,rheostat fixed in the tank. The dielectric property that is property of passing electrical force through it without the movement of particles of substance of fuel and the air vapor above it provides a way to measure fuel quantity. The capacity o tank will depend on the ratio of fuel and vapors in the tank.

Important points:

1. Fuel gauge has no major impact on the life of the battery as it uses only 0.15amp.

2. Fuel gauge works only when ignition is on.

3. Working of electrical fuel gauge does not depend on magnetic fields produced in the coils but depends on the current flowing through the coil. Thus vibration in voltage does not affect accuracy of the fuel gauge.