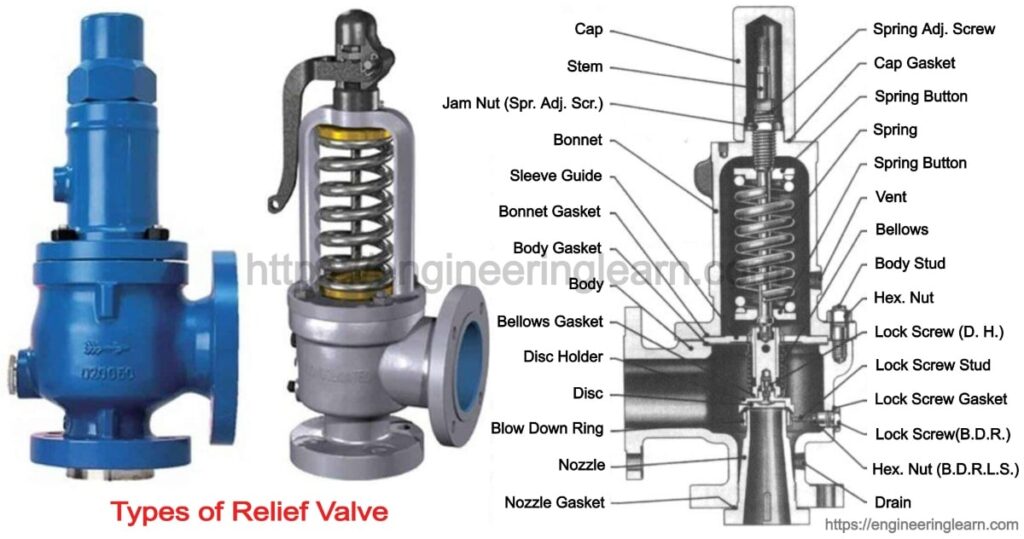

Types of Relief Valve: Function, Uses, Mechanism, Components, Application & Materials

What is a Relief Valve?

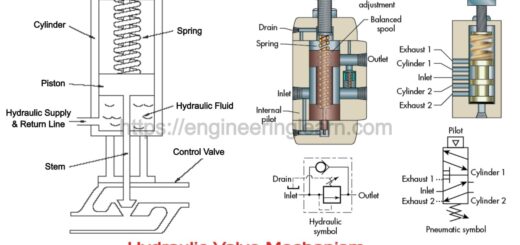

Types of Relief Valve ( Pressure Relief Valve ) : Function, Uses, Mechanism, Components, Application & Materials:- The relief valves are basically used to protect the hydraulic components from the excessive pressure. These are very essential for the safe operation of the hydraulic system.

Importance of Relief Valve

During the hydraulic circuit operations direction of movement of fluid is need to be controlled as well as flow rate of fluid is also controlled and in addition to these two factors pressure inside the system is also need to be controlled. If the pressure of the system is excessively high then that will damage the entire system there may be catastrophic failure of the hydraulic system, there may be bursting of the system and to avoid such failures of the system we should employ the pressure relief valves.

Functions of Relief Valve

The primary function of the relief valve is to limit the system pressure within a specified range. Relief valve is also used during the cooking operation as well. In similar fashion there are a lot of pressure control valves are used in the hydraulic industry. It is recommended for high pressure gas system relief valve outlet is in open air. In case when the outlet is connected with pipe system, then pressure get built up in the piping system which is in downstream of the relief valve. Sometime a bypass valve is used as a relief valve which is done for the safety of pump or gas compressor or any other equipment which is associated. A relief valve should be installed in vertical position; it might not perform correctly when it is installed in position which is other than vertical.

Uses of Relief Valve

Relief valves are used in wide range of operations of petrochemical, power generation, gas and steam for smooth operation. In chemical processing systems and refining these valves are used in multi- phase applications. But when there is high pressure and low pressure is not a concern then relief valve is not required. While operation, generally relief valves are closed till the upstream pressure reaches the set pressure. And the valve closes as the upstream pressure fall below the set pressure.

Applications of Relief Valve

Relief valves are used in wide range of operations of petrochemical, power generation, gas and steam for smooth operation. In chemical processing systems and refining these valves are used in multi- phase applications. But when there is high pressure and low pressure is not a concern then relief valve is not required.

While operation, generally relief valves are closed till the upstream pressure reaches the set pressure. And the valve closes as the upstream pressure fall below the set pressure.

Materials Used for Manufacturing Relief Valves

In general there are variety of materials used for various components of relief valve such as aluminum, stainless steel, brass, plastic, but the material used for spring which is provided inside the relief valve are generally made up of stainless steel or carbon steel. Most economical material is brass while aluminum is used where consideration is given to the weight. Plastic is used when cost is being reduced and stainless steel is used when fluid used is corrosive in nature.

The selection of material for relief valve is done on the basis of fluid property (if the nature of fluid is hazardous then the material should be such that it can discharge it safely) as well as temperature on which valve is being operated. One of the major disadvantage of the relief valve is it is subjected to the premature opening of valve when the device is subjected to bouncing movement.

Components of a Relief Valve

1. Valve Element

Valve element include spring loaded poppet which have elastomer seal. Upstream pressure and the spring apply opposite forces on valve. When the upstream pressure exerts force more than the force applied by spring then from the valve seat poppet moves away and results in passing of fluid from the outer port. When the force applied by the upstream pressure is less than the set pressure then valve closes.