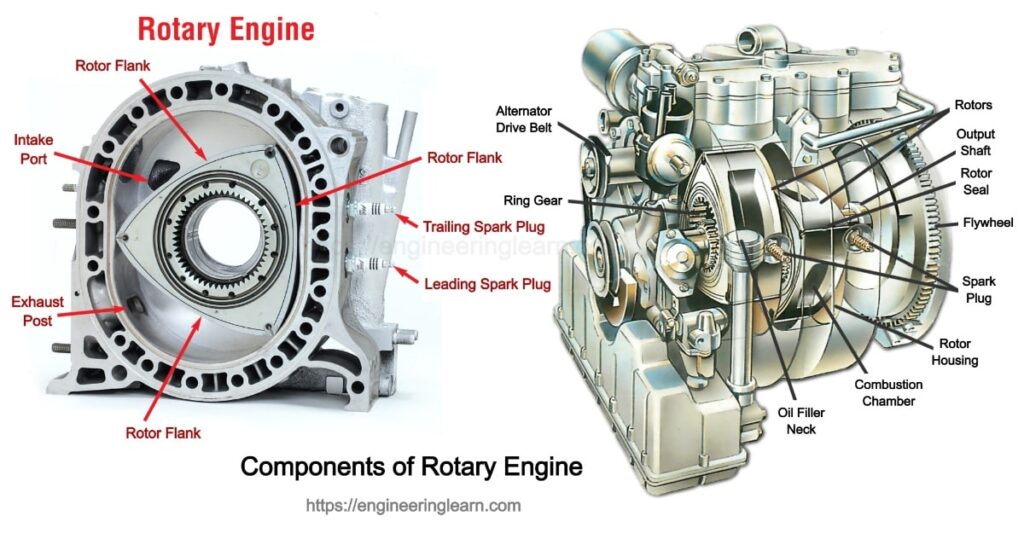

Components of Rotary Engine

Components of Rotary Engine :- Rotary engines are also commonly known as Wankel engines which are a type of internal combustion engine, which is used for converting the heat from the combustion of a high pressure air and fuel mixture into a useful work for the rest of the vehicle. It is a unique characteristic in a triangular rotor, which performs a task as a piston of a reciprocating engine which would work in a different manner.

Components of Rotary Engine

It is a hallucination that rotary engines are complicated whereas they do not have many moving parts and components as that of a piston engine. So let’s have a look on some of the most essential components of a rotary engine in order to give you a better sense of its working.

1. Rotor

A rotor refers to a three-sided component which is found having concave sides and is designed to give a gas-tight seal if pressed against the side. On every face, the rotor has an inlet or pocket, which is installed for a greater volume of gas, in order to effectively increase the displacement rate of the engine.

The rotor is found moving on gears that are attached to the shaft at the centre of the housing. These gears are responsible to allow it to spin in such a way that the edge of each side remains in contact with the housing, in order to maintain three individual combustion pockets.

2. Housing

The housing refers to as the main body of a rotary engine. It is found to have an oval shape and is designed to maximize the displacement of the engine and intending to allow the rotor to spin with its edges in consistent contact with the all the inner walls of the housing.

The rotor spins inside the housing, every gas pockets undergoes four sections of the combustion cycle, which include steps from intake, compression, combustion and exhaust. The spark plugs and fuel injectors are directly installed from the wall of the housing, whereas the outside channels passes the oil and coolant through the system, in order to maintain the integrity and the temperature of the system.

3. Output Shaft

The output shaft is responsible for transferring the energy which is generated by the compression and combustion to the drive train, which mainly gives power to the wheels. The shaft is mounted with round lobes on its own, which comes in direct contact with the rotor intending to spin the shaft.

How Does A Rotary Engine Work?

In an engine, combustion acts directly on the set of pistons which produces a linear movement inside the cylinders of the engine. The pistons moves up and down which are attached directly to the crankshaft. This is the component which is responsible for converting it into an up and down motion and gives it a circular motion that helps in driving the wheel.

In a rotary engine, all the main internal components move in a particular circular motion therefore it is simple and more efficient to transfer the energy from burning the petrol and turning the wheels. The rotary has very few moving parts which are smaller and lighter and even more powerful than its capacity.

Similar to conventional piston engines, the layout of the rotor of the rotary engine can be duplicated for a higher capacity and more power. Most of the rotary models were known twin rotors.

Advantages of Rotary Engine

There are three well known advantages of a rotary engine which should be known to everyone.

- Smooth running: The rotor delivers the power very smoothly as there is no reciprocating part, and the large rotating mass of the crankcase acts as a flywheel.

- Increased cooling: Whenever the engine runs, the rotating crankcase assembly makes arrangement for its fast cooling through the airflow.

- Weight Benefit: The rotaries which are shared with any other radial configuration, the engines has an advantage of a small flat crankcase. The better air-cooling imparted by the moving engine means that the cylinders can be made with thinner walls and cooling fins. The ratio of its power-to-weight was enhanced in comparison with the engines which demanded an additional flywheel for proper and smooth running.

Disadvantages of Rotary Engine

The designers of the engine had been kept aware about the demerits of rotary engine. Therefore it is important to know some of the demerits of such engines.

- The rotary engines had a fundamentally inefficient total-loss oiling system which intends to reach the whole engine. The medium of lubrication needs to enter the crankcase through the hollow crankshaft as the centrifugal force of the revolving crankcase is opposed directly to any re-circulation. The only practical solution to this was to lubricate it with the fuel and air mixture, mostly for two-stroke engines.

- More is the increase in the mass and size more increased will be the power multiplied by gyroscopic precession from the mass rotation of the engine. This produces stability in the aircraft in which these engines were installed initially, especially for pilots with less experience.

- Power output increased in order to overcoming the air-resistance of the spinning engine.

- Engine controls resulted in a lot of fuel waste.

Disadvantages of Rotary Engine

- Sealed fate : The special seals or faces or apex seals which help in creating the required compression for combustion is prone to wear. Whenever this happens the rotary engines starts to lose power and can burn its oil too which results to replacing the seals which is a tedious task.

- Emissions and economy: As the characteristic of power in a rotary engine is quite impressive, but it is not the same when it comes to fuel economy and its negative impact on the emission. Turbocharging and catalytic converters were the later designs which helped till an extent but not completely.

- Power absolute: As the revving nature of a rotary engine is free, it makes the cars powered by them engaging. But it comes at a cost to low-end power and especially torque. This performance limits the delivery of the engine to a specific application.