Different Types of Jacks

Different Types of Jacks

GENERAL INTRODUCTION:

Jack: A jack is a hydraulic or mechanical lifting equipment used to lift vehicles (cars/bikes etc.), entirely or partially, from the ground in order for maintenance or repair to be performed.They require very low amounts of energy to lift a car to any height and gain a safe and secure base to carry out important mechanic work.

Car jacks seem to have much more use than rather what we think of as just changing a flat tire. With that said, tires should be taken care of throughout the year and a suitable good jack is an extremely important piece of equipment if they need to be changed anytime.They are very important for performing various regular maintenance and work related to repairs, carrying out inspection of brakes, and the vehicle undercarriage. A jacked-up vehicle gives its owner of a hassle-free complete experience, including work related to damage repair.

TYPES OF JACKS:

- Scissor jacks

- Floor jacks

- Bottle jacks

- Pneumatic jacks

- Hi-lift jacks

- Strand jacks

- Trolley jacks

- Motorcycle jacks

- Fork-lift jacks

- Hydraulic jacks.

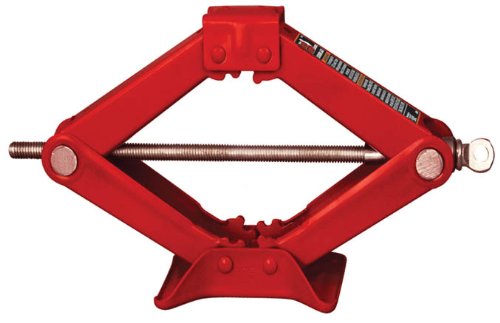

SCISSOR JACK:

The scissor jack is simply put the simplest type of jack and comes as standard equipment with many passenger vehicles. Instead of working on principle of hydraulic pressure, it works on the principle of screw mechanism. It is small in size, easy to carry and portable, capable of being fitted in a confined space, and is said to be one of the main types of car jack to be used. Most often than not, there is a marked area under the vehicle where this jack fits when trying to lift your vehicle. It finds its main use in minor repairs and in changing tires.

FLOOR JACK:

The floor jack is a jack which people more often can relate to or sees more widely, and fits perfectly for auto repairs because of its design which is considerably low profile. It is safe to say that it is one of the most popular car jacks. It can be rolled on steel wheels present beneath to any point below the vehicle, and the pump handle which is long raises the jack, hence resulting in lifting of the vehicle. This equipment uses the principle of hydraulic pressure and usually comes fitted with a release valve on the top of the handle on most of its variants. Some may find it useful for projects related to light construction such as installing a staircase, etc. It finds its much use in increasing the ground clearance vehicles, Vehicle and equipment maintenance and repairs, and in Light construction projects.

BOTTLE JACK:

Another jack with hydraulics principle behind it, the bottle jack is also a common piece of equipment in automotive industry. It usually has a pump handle and/or an attachment consisting of air compressor, and its only disadvantage is its size and shape, because of which, it finds really hard to work with low profile locomotives. Varying on the model you choose, these can lift somewhere from a range of 4 and 50 tons. It finds its use in automotive repairs, some high-clearance equipment maintenance and in medium to heavy construction projects.

PNEUMATIC JACK:

Also widely regarded as a telescope jack, the pneumatic jack is one of the most common used jacks in the industry related to heavy machinery maintenance for lifting buses, trucks, and construction related locomotives. They are highly not recommended for vehicles of small dimensions. This is widely used in heavy machinery, construction work, etc.

HI-LIFT JACK:

For the ones who are off-roading geeks, you might have seen a hi-lift somewhere or the other on a trail. Also regarded as a farm jack, these are taken into use when lifting/pulling a vehicle out of the mud or when there is a requirement of a wench, etc. These are rated to lift weight of nearly 7,000 lbs. and can lift a car up to the height of 5 feet off the ground level. This jack finds its use in off-road vehicle lifting, farm equipment maintenance, wenching.

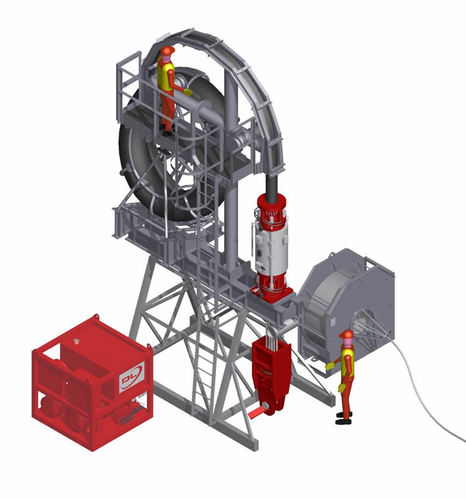

STRAND JACK:

If there is a requirement of a heavy-duty lift, a strand jack is up for the task. These find there use most often in construction work and engineering, and are capable of carrying out heavy-duty work like lifting bridges, power stations, and several other larger, heavier piece of equipment. It finds its main use in heavy-duty lifting, construction and engineering, etc.

TROLLEY JACK:

Another important choice of jack for automotive work, the trolley jack can lift weight of up to 4 tons, and can roll across obstacles like mud and gravel, has a reliable braking mechanism, and is one of relatively safer and easier jacks to use which has many applications. It finds its main use in automotive repairs, some high-clearance equipment maintenance, medium to heavy construction projects, etc.

MOTORCYCLE JACK:

Because of their low-profile, small work-stations or engines, working on motorcycles can be a task involving high expertise. A motorcycle jack is supposed to lift the entire assembly off the ground level, giving a relatedly easy access to its vital parts. It can also be used for ATVs (All Terrain Vehicles), and with some modifications, can find its use in even some of the snowmobiles. It finds its main use in motorcycle repairs and in ATV and snowmobile maintenance etc.

FORKLIFT JACK:

Also widely regarded as a pallet jack, this type of jack operates in a more or less similar capacity as a bottle jack and floor jack if combined. It has a steel handle, has an elevated in design, and the push rod is a considerable bit longer than the regular bottle jack. It can lift weight of up to 8800 lbs. without breaking a sweat. It finds it main use in warehouse, shipping and receiving, etc.

HYDRAULIC JACK

Operated with the help of a crank handle, a hydraulic mechanical service jack is of high importance and has a lot of uses, but most commonly we see them as the landing gear of different types of trailers, be it semi, boat, etc., and 5th wheel RVs.A hydraulic jack initially creates pressure by passing oil through two cylinders with the help of a pump plunger. The pump plunger is then retracted back, which results in opening of the suction valve and draws oil into an area which is known as the pump chamber. As the plunger is further pushed downwards, the oil is then passed through an external valve discharge and inside the chamber known as cylinder chamber. The suction valve then gets closed, resulting in built up of pressure inside the chamber; causing the piston present inside the chamber to rise and lift the object of interest. This process can be repeated as many times as you want, allowing your load to be lifted further up and higher. It finds its main use in trailers (boat and hauling), recreational vehicles, etc.