Knife Edge Gate Valve Working and Types

Knife Edge Gate Valve

Definition:

The knife edge valve or knife edge gate valve is a heavy duty valve which works with the highly viscous fluids.

When the paper industry needed a valve that could handle stringy pulp, these valves were designed. Using the normal gate valve, it was found that the pulp getting stucked in between the wedge and the seat, preventing flow shut-off. The knife edge valve was designed with sharp edges to cut through the pulp and seal the valve properly. This valve is specifically designed for corrosive, very viscous, and abrasive fluid media. It operates by enabling viscous fluid media to flow freely across seals with minimal interference. As the valve need to shut off, the knife edged gate comes down by cutting off the flowing media and seal the valve. The generally used knife edge valve is shown in Figure 1.

Figure 1

Working principle of Knife Edge Gate Valve:

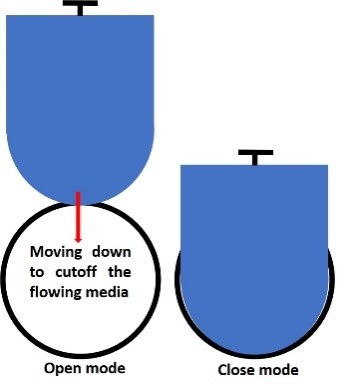

The knife edge valve may look similar to the butterfly valve, but its working principle is very different to each other. In the butterfly valve, the valve disc used to swivel around any fixed axis and thus performs the opening and closing operation of the valve. But in case of knife edge valve, the disc is replaced by a gate which moves up and down to perform the open and close operation of the valve. The edge of the gate is sharp enough to easily penetrate through the flowing media and takes its seat to close the valve. If the edge of the gate is not sharped, the thick flowing fluid may wedge in between the edge of gate and the seating. This may nay incorporate the proper sealing of the valve and hence hampers the flow operation. The Figure 2 shows the general working of the knife edge valve which is already described above.

Types of Knife Edge Gate Valve:

However, the knife edge valve is itself a type of parallel gate valve, but it can be further classified on the basis of its shape, actuation and materials. There are generally two shapes of knife edge valves used; circular and square, as shown in Figure 3. The shape of knife edge of the gate also changes with the change in valve shape, such as for circular valve, circular edged gate is used and for square valve straight edged gate is used.

(b) Square

On the basis of actuation, the knife edge valve can be subdivided into manual, electrical and mechanical type. The hand wheel is used in the manual type, stepper motor for the electric type and the pneumatic cylinder for the mechanical type. The materials used for manufacturing the valve body and gate is SS304 and SS316. But, sometimes to reduce the cost it is also made up of mild steel.

Advantages:

Knife gate valves are popular because they are cost-effective, simple to use, and light. They’re also quite useful in a variety of industries and operations. Knife gate valves have a sharp edge that cuts through the pulp and seals it.The knife gate valve has shown to be quite effective in applications requiring slurry, viscous fluids, and other systems where impingement is a concern.

Limitations:

Knife gate valves should only be used for applications that require a completely open or completely closed position, and should not be used to regulate flow unless they are specifically intended for that purpose. A vibration occurs whenever fluid is pressed against a partially closed gate, progressively eroding the disc and seat.

Applications:

In many processing industries, a knife gate valve can be found. Larger sizes are available to handle thicker flows of heavy oils, light grease, slurry, pulp, varnish, and wastewater. It’s worth noting, however, that knife gate valves have low-pressure limits.