Air Compressor Types and Working Principle

Introduction of Air Compressor

Air Compressor Types and Working Principle :- Air compressors are referred to as some of the most necessary appliances which are found mostly at the construction sites, as they are found using the power source for the electric tools. There are numerous types of air compressors, each one having its own unique capabilities as well as drawbacks. Therefore, the air compressors are mainly categorized as either positive displacement or dynamic displacement, which is based on their internal mechanism.

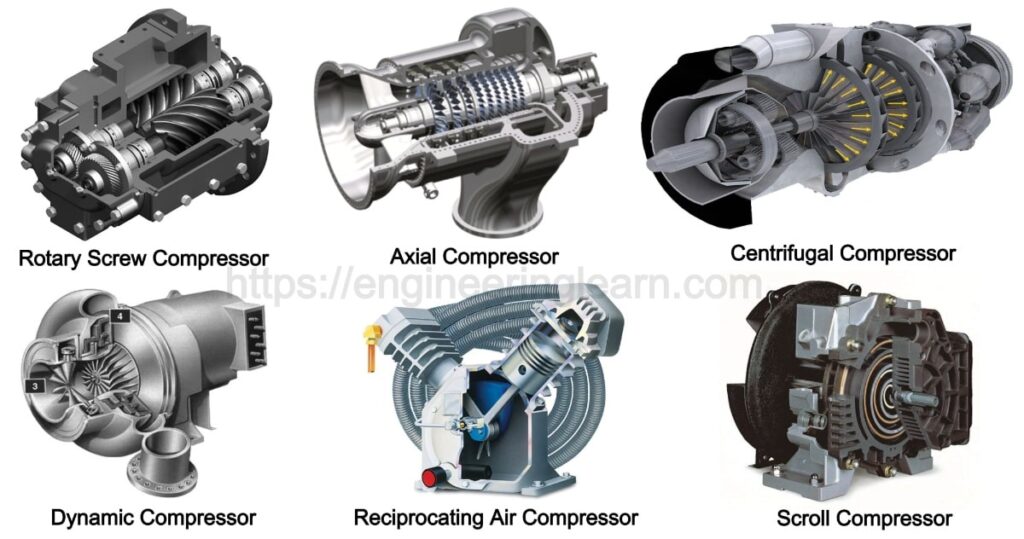

Types of Air Compressor

The Four most common types of air compressors which are commonly known are as follows:

- Rotary Screw Compressor

- Reciprocating Air Compressor

- Axial Compressor

- Centrifugal Compressor

- Positive Displacement Compressor

- Dynamic Compressor

- Isentropic Compressor

1. Rotary Screw Compressor: ( Types of Air Compressor )

Rotary screw compressors are referred to as those compressors which are a common type of displacement compressor. These are some of the easiest types of air compressors in terms of taking its care, as these are the machines which are equipped with an internal cooling system and does not require high maintenance. These compressors are found to be typically large as well as industrial-sized machines which can either be lubricated with oil or can even run oil-free.

These are the compressors which generate energy via two internal rotors which gets turned in the opposite direction. The air which gets trapped within the two opposing rotors, is responsible for building up pressure within the housing. Due to the internal cooling system, these are the air compressors which are designed for continuous use and also range in power from 5 horsepower to 350 horsepower.

Operation

Rotary screw air compressors are found quite easy to maintain and operate. The capacity control of such compressors is accomplished by the varying speed as well as the varying compressor displacement. There is also found a slide valve which is located inside the casing. As soon as the capacity of the compressor is reduced, the slide valve gets opened by passing a required portion of the compressed air back to the suction.

Advantages

There are various advantages of using a rotary screw compressor which includes smooth, pulse-free air output in a compact size along with a high output volume over a long life. The rotary screw air compressors which are found to be oil free, utilizes the specially designed air ends in order to compress the air without the presence of oil in the compression chamber in order to yield true oil free air. Oil free rotary screw air compressors are the ones which are air cooled and water cooled and also provides the same flexibility as that of an oil flooded rotaries whenever the oil free air is required.

2. Reciprocating Air Compressor: ( Types of Air Compressor )

Reciprocating compressor is referred to as another popular type of displacement compressor which is typically found at the smaller work sites like the garages and home construction projects. The reciprocating compressor is not similar to that of a rotary screw compressor as it is not designed for the regular use. A reciprocating air compressor is found having more moving parts as compared to a rotary screw compressor wherein these parts are lubricated with oil for smoother movement.

These are the types of air compressors which work via piston which is present inside a cylinder, which also compresses and displaces the air in order to build the pressure. Reciprocating compressors can also come in single or multi-stage variations, which can directly or indirectly affect the pressure ranges which can be achieved.

Single-stage and two-stage reciprocating compressors are specifically the machines which are used commercially. Single-stage compressors are generally used for pressures varying in the range of 70 psig to 100 psig.

The two-stage compressors are usually used at places wherever higher range of pressure is required. This can range from 100 psig to 250 psig.

The unit consumption in a reciprocating compressor is usually 1 HP ~ 4 CFM at 100 psi and that 1 to 50 HP. Compressors which are found to be 100 HP or above are typically Rotary Screw compressors or Centrifugal Compressors. Whenever there is a need of more power, the multi-stage compressor will be used. Whereas the single-stage compressors are the ones which can get the job done for smaller projects like woodworking and metalworking and multi-stage compressors are used to provide the power which is needed for intense construction like auto assembly and maintenance. Multi-stage reciprocating compressors are found to reach up to 30 horsepower.

3. Axial Compressor: ( Types of Air Compressor )

Axial air compressors are referred to as those compressors which are not typically used in the construction projects whereas are found in higher-speed engines on ships or planes. These are the compressors which are found having higher-efficiency rate but are highly expensive as compared to the other types of air compressors, and can get up to thousands of horsepower due to which they are mainly reserved for the aerospace research.