Types of Supercharger: Application, Method & Working Principle

What is Supercharger?

Types of Supercharger: Application, Method & Working Principle :- Superchargers are referred to as the pressure boosting devices or the compressors which are responsible for increasing the pressure of air before letting it move inside the cylinder of the internal combustion engine. The process of increasing the pressure or forcing more air to move inside the engine is referred to as supercharging.

Turbo Supercharger

Here the other component is found having more advantages as compared to a supercharger which is also referred to as a turbocharger, however this part is referred to as a supercharger or is also named as a turbo supercharger. This system is the one which offers power by the help of a turbine which is powered by an exhaust gas which is obtained at the end stroke of the combustion.

This is the first and the foremost difference which is created between the supercharger and the turbocharger from their power source. The crankshaft of an engine is responsible for driving a supercharger, while a turbocharger is powered by the exhaust gas which is waste but is produced during the process of combustion.

The primary function of a supercharger is to increase the amount of air that enters into the intake manifold. This helps the engine to burn more of fuel and do more work efficiently, hence increasing power.

Types of Supercharger

There are three types of superchargers which are commonly known to mankind. Scroll down to know more about these:

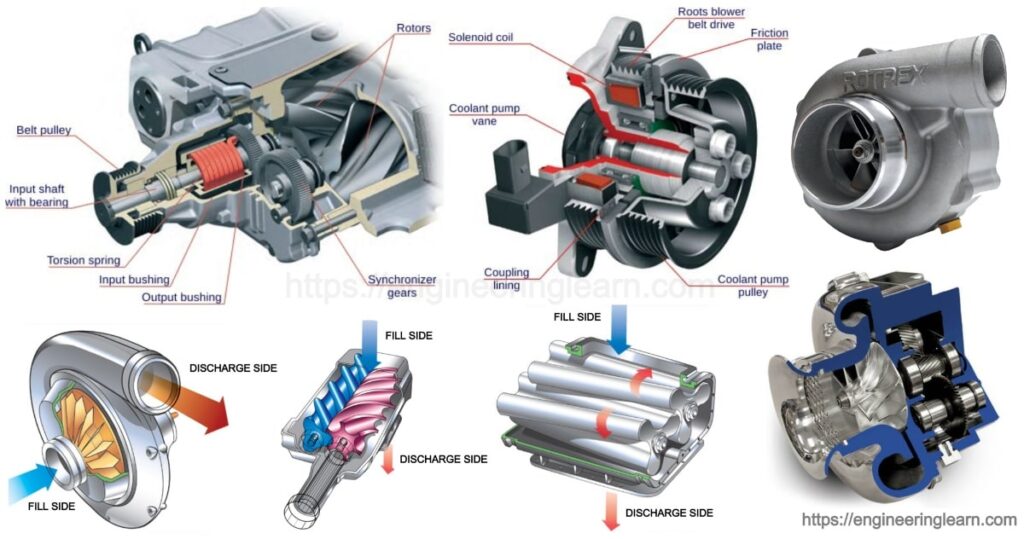

1. Centrifugal Supercharger: (Types of Supercharger)

These type of a supercharger consists of an impeller which can rotate at a comparatively high speed, approximately 10,000 R.P.M. The mixture of air-fuel is made to enter the impeller from the center which passes through the impeller and the diffuser vanes that goes out of the casing to the engine cylinder. Due to this high speed of the impeller the mixture is forced into the cylinder at a very high pressure.

2. Vane Type Supercharger: (Types of Supercharger)

This type of supercharger is the one which consists of a drum at which the number of vanes are mounted in such a manner that it can move in or out by the effect of some force so that they are kept in contact with the inner surface of the supercharger body always. The space available in between the body and the drum decreases from the inlet to the outlet side. Therefore, the mixture of air-fuel gets entrapped within the common two vanes from where the inlet goes in a decreased volume and the pressure gets increased as it reaches the outlet.

3. Roots Air-Blower Type Supercharger: (Types of Supercharger)

This type of supercharger are found having two rotors similar to that of an epicycloid shape. Both the rotor is fixed to a shaft using the key. The two shafts are connected together by the help of gears that are of equal size so that the rotors can revolve at the same speed. The working action of such a supercharger is quite similar to a gear pump so that the mixture at the outlet side is found having a high pressure.

The roots of a supercharger is quite easy in terms of construction and also on the same time is found requiring very low maintenance which means that it has a comparatively longer life. Also it is important to know that it works well at varying speed range. Comparing with centrifugal type of supercharger has a very poor working characteristics at lower speeds as well as the vane-type supercharger is found having problems of wear of vane tips.

Applications of Supercharger

It is important for everyone to know what all are the applications of a supercharger. Therefore, one needs to scroll down to know more of them:

- Superchargers are responsible for reducing the per horsepower weight of the engines as per the requirement of the aero engines.

- In order to decrease the space which is occupied by the engine as necessitated in the marine engines.

- In order to maintain the power of a reciprocating aircraft engine at high altitudes supercharger is quite helpful where there is less oxygen available for combustion.

- Superchargers are used in order to improve the volumetric efficiency of an engine at a comparatively high altitude, as in the aero engines and at high speeds as in the racing cars.

- In order to have a better turbulence it is ensured that more combustion completion gives a greater power and lower fuel consumption.

Methods of Super Charging

There are numerous methods to force in air which does not need any extra power like the compressor units. The 2 most widely applied methods are as follows:

1. Ram Effect Supercharging

This method of supercharging includes the inlet manifold which is designed in such a way that the air automatically gets pushed inside the cylinder. This air continuously to get into the cylinder but the intake valves open and close various times in a second. Whenever the valve gets closed, the air which is present just gets into it and generates a pressure wave that travels in the opposite direction until it hits the plenum & gets reflected back again.

There is a frequency called resonant frequency which if matches with the frequency of the plenum & engine the pressure wave carries more of air into the cylinder which does the work of a supercharger.

2. Under Piston Supercharging

This is a type of method wherein it is generally adopted in large marine engines and is utilized at the bottom side of the piston by compressing the air. With correct time span of the valves, the system gives an accurate supply of compressed air, as there are 2 delivery strokes to each suction stroke of each stroke

Working Principle of Supercharger

It is very important to know the working of a supercharger with these three major types available that includes centrifugal, roots and twin-screw. Let’s dive in to know more about the working principle.

The centrifugal types of supercharger are the one which use an impeller that draws and sucks air whereas the roots and twin-screws are quite different from the meshing lobes. The rotary power from the engine crankshaft boosts up the engine at the varying level.

The roots supercharger are one of the oldest version of supercharger which was patented in the year 1860 by Philander and Francis Roots in order to ventilate shafts. The project was introduced in an automobile engine in the year 1900 by Gottlieb Daimler. The working included the meshing lobes of the roots supercharger spin in order to trap it in air of pockets between the lobes. The air is held mostly between the fill side and the discharge side wherein the large quantities of air went inside the intake manifold and stacked up to create a positive pressure.

The roots supercharger is mostly located at the top portion of an engine due to its huge dimension. It is quite less efficient among the various types as it add higher weight to the vehicle. The pressure inside the cylinders is quite less as compared to the atmospheric pressure during the suction stroke. In case of a supercharged engine, the mixture is forced inside the cylinder at a higher pressure as compared to the atmosphere. Due to the increased pressure, the intensity of the mixture gets increased so its weight per stroke is increased for the same displacement volume. This increases the power output of the engine wherein the rate of fuel consumption is also increased.

Need of Supercharger

The power generated by an engine is referred to as its function of the mean effective pressure or the average pressure present in the cylinder. Here the power is kept directly proportional to the average pressure.

Power ∝ Mean effective pressure (MEP)

Pressure goes on increasing while the compression stroke goes on and decreases in the case of exhaust stroke. So the average pressure is calculated by calculating this data. From the above expression one needs to know that more the MEP higher will be the efficiency of an engine

In case the air is forced & is compressed into the cylinder, there will occur an increase in the mean pressure which will be responsible for producing more power. This creates its need in order to force the air into the engine. Thus they are also termed as forced induction systems. Forcing more of air into the engine clearly indicates higher density of air charge before entering the cylinder.

Considering the higher altitudes and hill stations where the density of air is quite less and the engine under action. So in order to compensate the power loss of engines and vehicles at higher altitudes superchargers are most important. Other than this the superchargers are responsible for letting the engine burn with higher fuel and do more working as each intake circle of the engine gets higher amount of oxygen. These are the power components which are driven mechanically by the means of a gear, belt, shaft or a chain that is connected to the crankshaft of the engine.

Merits and Demerits of Supercharger

Merits

- Superchargers are responsible for quite lower rpm boosts.

- Superchargers are comparatively reliable and less expensive.

- Superchargers are found not using the engine oil.

- Superchargers are found having less heat issues as compared to the turbochargers

Demerits

- The main constrain with a root superchargers is that it does not internally compress the air, which does not cradle of heat which is downside.

- All the superchargers are powered by the engine instead of the exhaust gases. Therefore, to power the supercharger a slight quantity of engine power is used and thus a loss occurs just by having a supercharger present over there.

- Superchargers have a high weight placement. So that the engine and the supercharger is placed on the top due to its dimensions.