Types of Punches: Applications, Precautions, Working Principle, Advantages & Disadvantages

What is Punch Tool?

Types of Punches: Applications, Precautions, Working Principle, Advantages & Disadvantages :- Punches are known to be made up of hard metal rod using a pointy tip at one end and a dulled end at the other which are often used in conjunction with other tools like hammer or chisel in order to cut and shape the blocks of materials. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged rivets, bolts, or pins and many more. Punches are referred to as the typical devices which is used to make a hole with their points.

Classification of Punches

There are numerous types of indenting rods available which are discussed above and are used to Centre punch or drift punch, pin punch or prick punch, used to prep a drill hole to any other metal sheet surface. These types of tool has a place in every toolbox and workshop bench. So, now let’s have a look on the classification and uses of different types of punches.

A) According To The Shape

Punches are mostly classified according to the shape of their points. The most popularly used punch amongst these is the prick punch which is quite helpful for placing the reference marks on metal sheets. These types of punches are used to transfer the dimensions from a paper pattern directly on to the metal. In order to take the reference correctly you need to place the paper pattern directly on the metal that too in the orientation in which you need to obtain the results.

B) According To The Slider Movement

Punches are classified on the basis of the movement of slider. These are further divided into 3 types. Single action, double action and three action punch, whereas the most commonly used punch is a single action punch.

Types of Punches Tools

If you ought to visit a workshop then you will definitely find various types of punches for their specific functionalities and uses. This article will help you in learning a lot about types of punches, so let’s gets started to learn all about punches.

1. Prick Punch: ( Types of Punches )

Prick punch is known as the most used and common type of punch in today’s professional world. Most of the people are found using this punch while transferring the dimensions from a paper pattern on to the metal and then to use them as a point of reference for cutting or fabricating purposes. Prick punches are found to be similar to centre punches which can have a narrow point and are also used for marking a design or layout.

Shifting the dimensions is mostly done during placing the paper pattern directly on the metal and in order to select its orientation properly and accurately. By hitting the punch lightly with a hammer, the pattern gets outlined on the metal which creates a slight indentations on the metal.

2. Centre Punch: ( Types of Punches )

Prick punch are quite adequate when it comes to take the reference marks for metals, but there are some metal works which require a larger indentation. So, with a Centre punch, it can make indentation along with the reference marks in metal that seem to be quite large for drilling activities. The Centre punches are found to be heavier as compared to the prick punch and also have a point ground at an angle of 60 degrees.

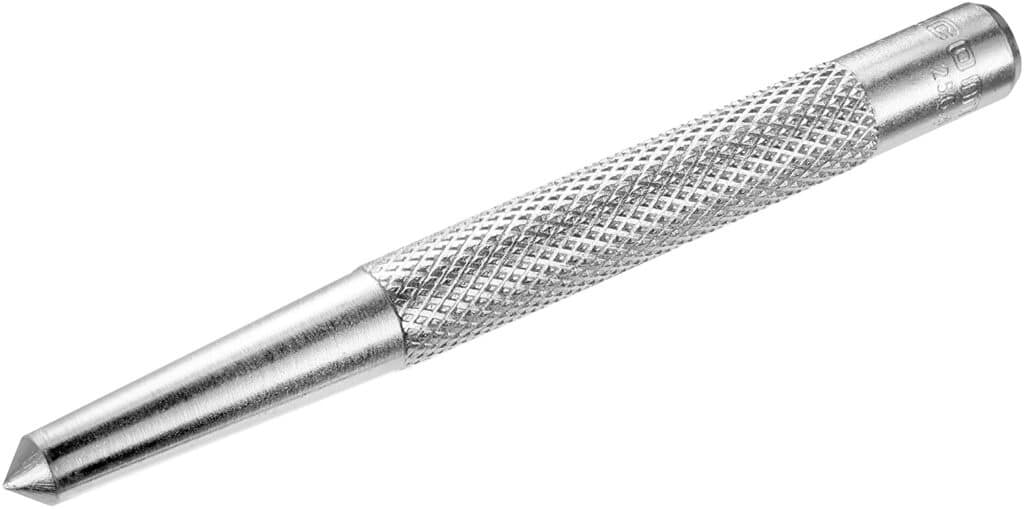

While striking a Centre punch as excessive force, an unnecessary protrusion and dimples around the created markings can be found. Centre punches are also used in order to mark the indentation for a guiding drill bits and to also identify a location on a surface. Centre punches are observed to be highly pointed, in order to obtain large circular indentations. These are also used as a prepping tool. The drill bit is found locking it against the punch mark after which the hole is made without any constraint. These types of punches are equipped with a knurled rod, which is an easy grip- tool and stops your drill from wandering.

3. Drift Punch: ( Types of Punches )

Drift punches are also referred to as drift pins and are mostly used to align bolt or rivet holes so that the fasteners can be inserted properly. In case there is a need to remove the damaged rivets, bolts, and pins which bound up in holes, then one must use a drive punch.

Drift Punch should be labelled as anti-drift tool as this member of the punch family is specifically designed to align the fastener holes. Using these once can gently hammer this punch into the holes unless and until it gets properly aligned and prepped for the fasteners, be it a rivet or a bolt. Once tapered, the body can also be used to widen the aligned holes.

Rather than the pointy ends, a drive punch usually comprises of a flat face. The width of this punch’s face is used to determine the type of punch whereas the sides of this punch are responsible for tapering down the face to some situations which would require you to use a punch with a straight shank. A punch with a straight shank is highly common and is known as a drift punch.

4. Pin Punch: ( Types of Punches )

A pin punch is found having a straight shank which has various applications in removing bolt or pin. The foremost purpose of pin punch is to finish the removal of bolts or pins from a hole which is already loosened up by a drive punch.