TYPES OF PRESSURE GAUGES

TYPES OF PRESSURE GAUGES

GENERAL INTRODUCTION

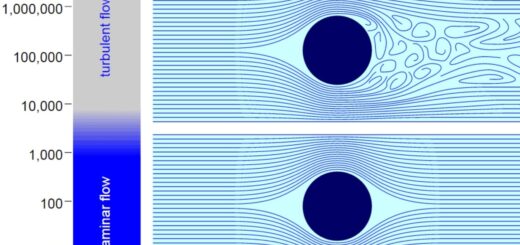

Pressure can be simply put as the normal force which is exerted by a fluid per unit area of the surface under consideration. This pressure can be measured with various methods using different types of instruments. In the study of fluid mechanics, we use some specific pressure gauges for measurement of pressure. Selection criteria of pressure gauges depends upon the type of fluid flow and its location.

Measurement of pressure is done by using the principle of manometry and different devices taken in use to measure pressure are referred as manometers. The branch of science which involves the study of pressure and pressure measurement is called manometry.

TYPES OF PRESSURE GAUGES

The different types of pressure measuring instruments are broadly categorized in two categories:

- Manometers

- Mechanical Gauges

A) MANOMETERS

Manometers are an elementary type of pressure measuring devices which function on the principle of balancing the liquid column with the similar or any another column of liquid. In the following process, using one column we measure the pressure not depending on the second column. It has following two types:

- Simple Manometers

- Differential Manometers

SIMPLE MANOMETER:

Simple manometer has a simple construction.It has a single glass tube with one end beingin attachment to gauge points whose pressure is under study and other open to atmosphere. We can easily calculate the pressure, by measuring thesimple manometer for rise of liquid. Simple manometer further has three below-mentioned types:

- Piezometer

- U-tube manometer

- Single column manometer

PIEZOMETER:

Piezometer is a simple type of manometer which finds its use in measuring the liquids of medium pressure range. A piezometer is a simple glass tube with both ends open. One end of the piezometer is in direct connection to the pipe line, vessel which contains liquid where pressure is needed to be measured and the other end isfree to the atmosphere. The glass tube is attached vertically upwards so that the liquid in it can freely rise in it and does not overflow. The pressure of the liquid is easily measured by rise of the height of the liquid using scale which is attached to it. Piezometer is considered to measure gauge pressure only because of the reason that the surface of liquid is in direct contact with atmospheric pressure. The major drawback of piezometer is that it cannot be used in measuringvery high pressure and gas pressure due to the one end which is open.

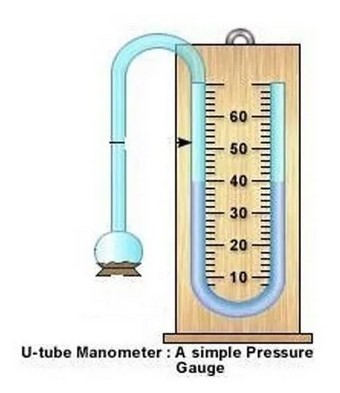

U-TUBE MANOMETER:

U-tube manometer is used to overcome allthe limitations which piezometer possesses such as piezometer cannot be used to measure high pressure, because for that piezometer must have long tubes which cannot be provided easily and thus, gas pressure can’t be measured by piezometers. By using U-tube manometer one can do both things. A U-tube manometer construction is such that it has a glass tube which is bent in ‘U’ shape. This shape is the reason we call it as U-shape manometer. One end of this manometer is open to atmosphere and other end is connected to the gauge points which are the point for which the pressure has to be measured. The tube of the U-tube manometer is filled with a fluid which is of a higher specific gravity as compared to fluid of which pressure is under consideration. This fluid is called manometric fluid. Most often these fluids are mercury, salt solution, carbon disulphide etc.These manometry fluids are used as per the needs. Mercury is a very common manometric fluid due to its vapour pressure which is very low. More than one manometric fluid can be used butthese fluids should have a considerable number of differences in specific gravity, otherwise they get mixed in the process. For low pressure measurement, fluids which have lower value of specific gravity are used and for measuring high pressures, those fluids are preferred which have high value of specific gravities, for example-mercury. We can measure the pressure by measuring the height of liquid present in the column.

SINGLE COLUMN MANOMETER:

Single column manometer is simply a modified U-tube manometer. In U-tube manometer two readings are to be consideredi.e., rise of fluid in one tube and fall of fluid in the second tube.This is where single column manometer comes in handy. Here, a reservoir which has a large cross-sectional area which has 100 times area than tube is connected to one leg. When pressure varies, there is a very small change in the level of limb but the variation of pressure can be easily observed in the corresponding limb due to attached scale. The change in the liquid level depicts the change in pressure. The thinner limb can be attached inclined or vertical as per need.

DIFFERENTIAL MANOMETER:

It is used when we need to measure the pressure difference between two points in pipe or in two completely separate pipes. Differential manometers contain two glass tubes which are bend whose ends are in connection to gauge points whose pressure differenceis under study. Below are the different types of differential manometers used generally:

- Two Piezometer Manometer

- Inverted U-tube Manometer

- U-Tube Differential Manometer

TWO PIEZOMETER MANOMETER:

As the name suggests, this contains two piezometer which are attached at the two different gauge points whose pressure difference is under consideration.The pressure difference between two points can be easily studied by observing the difference in the liquid levels raised in the two limbs.

INVERTED U-TUBE MANOMETER:

Inverted U-tube manometers are used for underground pipelines and in these manometers, the manometric fluid density is lesser than the flowing fluid density. As per the name, it contains of a U-shape glass tube which is invertedly held. In general, air is used as manometric fluid in them due to its lower density. The points of the manometer are in direct connection to gauge points whose pressure difference is to be studied. The height difference of the liquids of both the arms gives the pressure difference. At the top of the inverted U-tube, an air lock is attached which aids in rising of the liquid to a considerable height in both the arms by driving out compressed air.

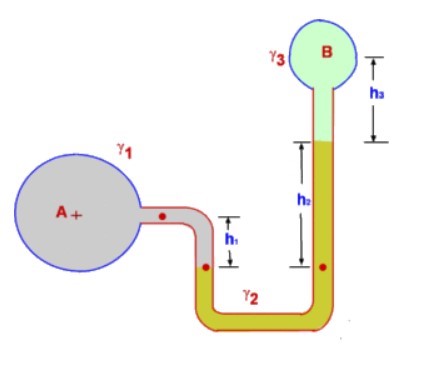

U-TUBE DIFFERENTIAL MANOMETER:

As the name goes, it consists of a glass tube of U-shape. The two different ends of this tube are in direct connection to the two-gauge points between whom the pressure difference is under study. In the middle of this tube, manometric fluid of higher specific gravity is filled when comparing to the liquids, whose pressure difference has to be determined. By measuring the heights in two arms, measurement of the pressure differenceusing U-tube differential manometer can be easily carried out.

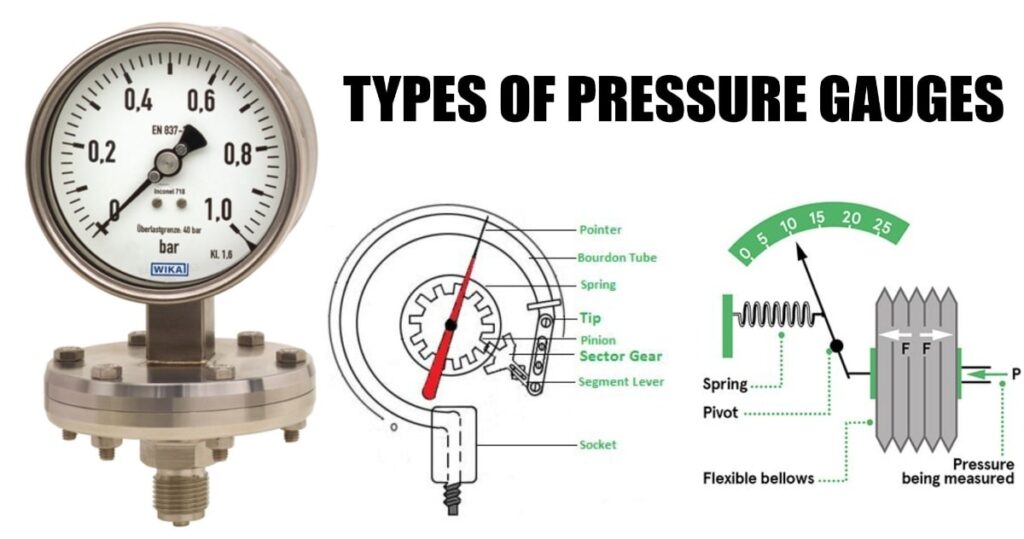

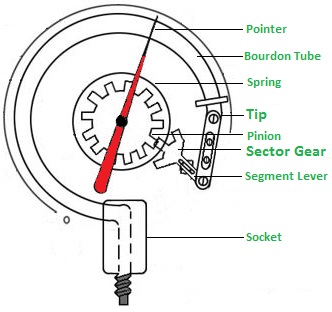

B) MECHANICAL GAUGES:

Mechanical gauges are used to determine very high pressure but have comparatively have less accuracy. These mechanical gauges contain an elastic element which undergoes deformation on pressure application. This deformation is magnified further by gear& pinion setup done to a pointer scale and then pressure is determined. Given below are thepressure gauges which are used mostly in the industry.

- Bourdon Tube pressure gauge

- Diaphragm pressure gauge

- Bellows pressure gauge

BOURDON TUBE PRESSURE GAUGE:

Bourdon type is the pressure gauge which is used more often in the industry. It is usually made of either steel or bronze tubes. Here, this tube functions as the pressure responsive element. One end of this tube is connected with pressure inlet and the other one is closed at the other end. Under initial conditions, the cross section of this tube is elliptical in shape, but as soon as the gauge is in connection with the gauge point, fluid under pressure enters into the tube, due to which the shape of the tube under consideration changes from elliptical to circular. The end which is closed of the tube is free for movement. A small movement of the free end of the tube is transmitted with the help of some linkages to the pointer moving in the clockwise direction. The pointer shows the actual pressure of the fluid with the help of dial indicator. When pointer moves in anticlockwise direction, it indicates that it shows negative vacuum or gauge pressure.

DIAPHRAGM PRESSURE GAUGE

This device is taken in use to measure low pressure intensities when compared to Bourdon tube. Here the pressure responsive element is the elastic steel corrugated diaphragm. Its operation is somewhat similar to Bourdon tube.The pressure is observed by using needle whose movement is governed by the diaphragm with the help of pinion arrangement with it.

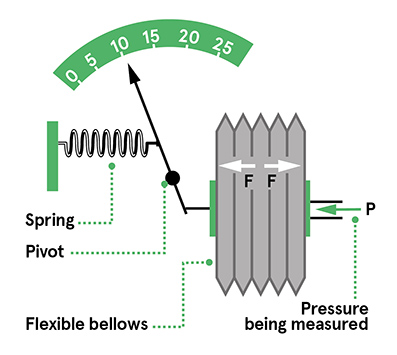

BELLOWS PRESSURE GAUGE:

In this instrument, the pressure responsive components are made up of thin metal tubes with deep corrugations on its circumference.When there is a change in pressure,there is either expansion or contraction in the elastic elements. A pointer is also included in the system which gives the reading on circular dial. When there is an increment in pressure, it expands and when there is a pressure decrement, the elastic elements in bellows pressure gauges experience contracts.