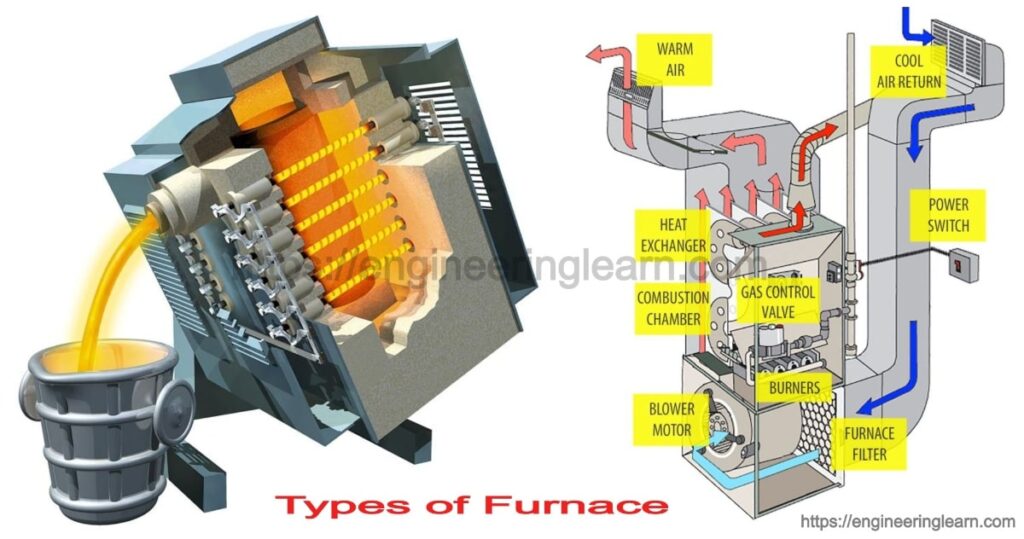

Types of Furnace and How They Work in Homes & Industries

What is Furnace?

Types of Furnace and How They Work in Homes & Industries :- Furnaces are referred to as those devices which are found to generate the heat in a controlled manner through the combustion of a fuel source. The thermal energy is found to be used to heat the spaces like the rooms, buildings or other structures. Other furnaces can be used in commercial as well as industrial settings in order to process the materials.

Different Types of Furnace

This articles aims to make you learn about the different types of furnaces will can be explored, summarized mainly under these two broad classifications:

- Types of Industrial Furnaces

- Types of Furnace for Heating Homes and Buildings

A) Types of Industrial Furnaces

Furnaces in the industrial settings are found to heat up the materials by using fuel and combustion gases. These materials may be in direct contact with the fuel and its gases like blast furnaces or in indirect contact with the fuel but still in direct contact with the gases or indirect contact with both fuel and gases. In all the cases the goal remains the same which is to attain a higher level of heat.

One of the primary consideration while selecting an industrial furnace is typically considered as the range of operating temperatures which the furnace can provide. Furnaces which reach higher temperatures are found to cost more. The main aim of an industrial furnace is the temperature efficiency uniformly.

Some of the most common types of furnaces are those which are used for metals and materials processing and are mentioned below:

- Bell Furnaces

- Box Furnaces

- Forging Furnaces

- Pit Furnaces

- Salt bath Furnaces

- Tempering Furnaces

- Vacuum Furnaces

1. Bell Furnace: ( Types of Furnace )

Bell furnaces are usually those which are electrically heated, gas-fired or thermal recirculation heating system which features a movable dome. This furnace hood can be lifted frequently throughout the vacuum or can also be controlled through the atmosphere processes.

Bell furnaces are used to temper, anneal, normalize and stress relieve the steel plate formed parts. This equipment is mostly used with multiple bases and is still found to provide reliable seals. These furnaces either multi or single stack are used to treat the coils, strips, sheets, rods and more.

2. Box Furnace: ( Types of Furnace )

Box furnaces are the ones which are usually used for heat-treating, calcination, curing, preheating, tempering and other processes. The box furnaces feature vertical lift or swing open doors which insulates the furnace and ensures consistent airflow management.

Box furnaces are also referred to as the ones which accept heavy loads and are set up to be loaded through roller hearth, or any other manual process. There are various gas and electric versions available in the market which are able to uniformly treat large material volumes due to which the box furnaces are seen in most of the laboratories and industrial applications.

3. Forging Furnace: ( Types of Furnace )

Forging furnaces are referred to as the ones which are mostly used for the purpose of pre-heating, slot forging furnaces which quite resembles to a pizza oven. These open-hearth furnaces are those which transmits the heat via radiation in order to get metals to a temperature at which they can be forged or to also stop the hardening processes.

Heavy duty forging furnaces usually either heat or reheat large steel ingots, blooms and parts. These furnaces are found to come in Forging Box style. The type of load charge and discharge can be automated in some of these furnaces.

4. Pit Furnace: ( Types of Furnace )

Pit furnaces are referred to as those furnaces which are available in gas-fired or electric-powered configuration. These furnaces are also referred to as the top load furnaces which is Offered in many sizes. The pit furnaces heats to various temperatures within a secured working chamber along with a controlled atmosphere. These furnaces are mostly used in automotive and aircraft part by manufacturing as well as machine building, wind energy and mining.