Cabinet Scraper Working and Types

Cabinet Scraper Working and Types

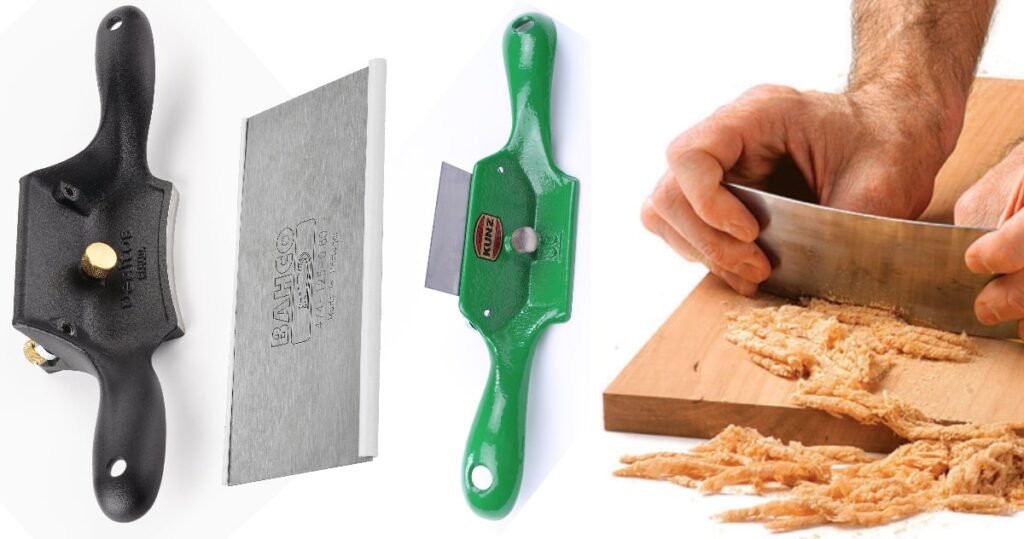

Cabinet scraper is also known as card scraper but the only difference between both of them is that the card scraper is card shaped without any grips and the cabinet scraper has grips. It is a finishing and woodworking shaping tool. It is generally used for manually removing less amount of material and excels grain areas where tear out can be caused by hand planes. For working with hardwoods cabinet scraper are very suitable and it can be frequently used in place of sandpaper. They provide very clean surface in comparison with sandpaper. Cabinet scraper does not clog the wooden pores with the dust. Fuzz of torn fibers is not left by the cabinet scraper as the finest abrasive do.

Types

- Cabinet scraper is available in different size and shapes but the common type is rectangular shape of 2 inch x 7 inch with the thickness of 0.024 inch to 0.039 inch. It can be fabricated according to the requirement of size.

- Gooseneck scraper is another common configuration which has the shape which resembles French curve and they are useful in scraping the curved surfaces like convex surfaces. Commonly used for scraping surfaces of the violin fingerboards.

- For manufacturing complex moldings, a card scraper is used. They cut the negative according to the desired molding in the steel by die cutting or through filling. Scratch stock are the card scraper which is held by an adjustable stop.

Generally the scrapers are made up of high carbon steel. Scrapers are available in wide varieties of style by the manufacturer but many woodworkers make their own scrapers by just cutting them with the help of old hand saw blades.

For working with ceramics, card scrapers are used because the card scrapers substitute for more tradition wooden rib. For trimming damp or dry clay, scraper can be used. For fine finish works, there are super thin scrapers are also available having thickness of around 0.25 mm, they can be used by one hand because they are very light.

Working

For using a scraper, it is held between the fingers on one hand in either side and are made inclined to the direction in which scraper are made to travel. The angle for which the scraper is inclined can leads to the effective angle for cutting edge. Only practice can leads to the identification of correct angle. With this inclination, the scraper is bending slightly by holding it with providing pressure at the center with the help of thumbs and at the edges with fingers. By providing slight bending the scraper corner are slightly lifted which prevents the scraper from marring the work piece and it can also increase the depth of cut.

And then the scraper are drawn toward or pushed away alternatively, but woodworkers claims pulling the scraper toward leads to the development of dip which results in uneven surface

One of the major disadvantage of the card scraper is that their use is even difficult for the skilled worker therefore it needs practice for the identification of correct bend required for scraping.Friction created due to the use of scraper can results in heating of the scraper which can even burn fingers.

Advantages

- It is very precise.

- It provides even finish which is smoother than the sandpaper.

- It is a very essential tool which is used for leveling a hardwood top.

- It can remove dried glue, paint or any tricky grain.

- It can reduce the risk of cutting through material which is of less thickness.

Disadvantages

- Skilled labor is required.

- Cabinet scraper is slow in comparison with hand plane.

- They are not suitable to use with softwoods like spruce, pine etc.

- It is very slow in removing material but still faster than the sandpaper.

- When using card scraper then heating due to friction is a problem.

- Frequently sharpening of the cabinet scraper is required for preventing the damage to woods.

Uses

- They can remove fine shavings of wood.

- It can be used for trimming off edge banding’s extra lip which was missed by edge band trimmer.

- They are used by cabinetmakers and woodworkers for removing small amount of wood for providing level and shiny surface.

- Cabinet scrapers can also be used for the removal of stain or paint from wooden surface.

The process of sharpening of cabinet scraper is classified in four steps:

- Rough edge: In this step, the newly bought scraper has their rough edges.

- Squared edge: In this step, the rough edges of the scraper are made smooth.

- First pass: This is a optional step in sharpening of scraper in which the upper edge of the cutting component was burred downward.

- Turning of burr: In this step the scraper edge are made burnished with the help of burnisher. The edge of the scraper is joint at right angle with the face of the scraper which result a fine burr formation on both the sides.