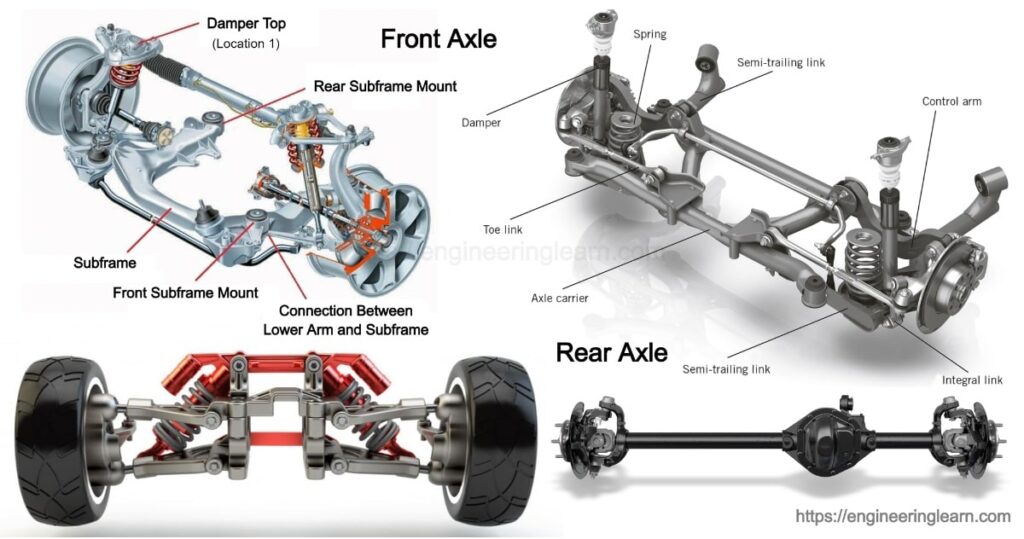

Types of Axles

Types of Axles :- The axle is a shaft used for rotating and supporting the wheels of an automobile. Axle plays very important role in automobile. On one side, the axle is attached to a differential via sun gear and on the other side it is connected to the wheels.

In some cases, the axles are fixed to the wheels and rotate with wheels while in some cases axle is fixed to vehicles and only wheels can rotate with respect to the axle. Bearings are used to for the second case .

Types of Axle

Axles are classified into three categories:

1. Front axle

2. Stub axle

3. Rear axle

1. Front Axle: ( Types of Axles )

Front axle is placed on the front side of automobiles. Front wheels are mounted on it. Front axle is generally made of I-section in middle portion and circular or elliptical at the ends. This cross section helps axle to withstand bending due to high loads applied by vehicle weight and torque during braking.

The main functions of front axle are:-

• It supports the front part weight of vehicle

• It absorbs upcoming shocks by using shock absorbers

• It facilitates steering mechanism

A) Dead Front Axle

The dead front axles are the axles, which are fixed and do not rotate with the wheels. These axles have high strength and rigidity to support vehicle. The ends of the front axle are designed to accommodate the stud axles.

B) Live Front Axle

The live front axles are the same as dead front axles, there is only one difference that live front axles are used to transmit the power from gearbox to the front wheels in front wheel drive vehicles. It rotates with the front wheels.

2. Stub Axle: ( Types of Axles )

Stub axles are generally used in front wheels. Wheels are connected to the stub axle by means of kingpins. It is made of nickel steel and alloy steel which contains chromium and molybdenum. It turns on the pinned pin which is used in light drive. The axle beam eye is locked by taper cotter pin.

Bushes made of phosphor bronze are installed into the fork ends of axle to provide bearing surface for the kingpin. Forces acting on vertical direction are supported by a steel washer or a thrust bearing placed either on the top fork or between lower fork and the underside of the axle beam.

(a) Elliot: – To connect to the front axle, this stub axle uses a yoke, a cotter and a kingpin.

(b) Reverse Elliot: – This type of axle has a layout opposite to the Elliot stub axle.

(c) Lamoine: – This Lamoine stub axle has a L shaped spindle instead of a yoke hinge.

(d) Reverse Lamoine: – It is just the opposite of the standard Lamoine axle.

3. Rear Axle: ( Types of Axles )

Rear axle is placed in between the differential and the driving wheels to transmit power from the differential to driving wheels. It is employed on the vehicles which are rear wheel drives.

Bearings are provided on rear axle. The vertical load, which comes onto the axle casing, through the springs, is transmitted through these bearings to the shaft and hence the wheels to the ground. The reaction of this load between the wheel and the ground act upwards on the wheel.

A) Semi Floating Axle

A semi floating axle has a bearing located on the axle and the inside the axle casing. It has to support all the loads of vehicle. The inner end of axle is supported by the differential side gear. The wheel can be bolted directly to it, as the outer end is flanged. In some axles the hub of the wheel is keyed to the outer end of the axle. The vehicle load is transmitted through the casing and the bearing which causes the bending or sharing of the axle. Semi floating axle is the most basic axle among all the other types. It is cheap also and that’s why it is widely used in cars.

Advantages

• It is simple in design

• Manufacturing cost is less

B) Full Floating Axle

A full floating axle has two deep groove ball or taper roller bearings, located between the axle casing and wheel hub. The outer part of the axle is made flanged which is voltage two wheel hub. The axle is not supported by bearings on either ends. The axle is relieved of all strain caused by the weight of the vehicle on and trust. It transmits only driving torque. This axle may be removed from the housing without disturbing the wheel by removing the nuts. This type of axle is more expensive and heavier than the other axles.

C) Three Quarter Floating Axle

In three quarter floating axle a bearing is located between the hub and the axle casing. Hence the weight of the vehicle is transferred to the axle casing. The side thrust and driving torque are taken by the axle. Axle is attached rigidly to the hub. It helps in providing the driving connection and maintaining the alignment of the wheel. The inner end of this axle has the same construction as that of semi floating axle. It is more reliable but its construction is not simple.

Image Source :- wisegeek, researchgate, spicerparts