Cylinder Liner Types and Function

What is a Cylinder Liner?

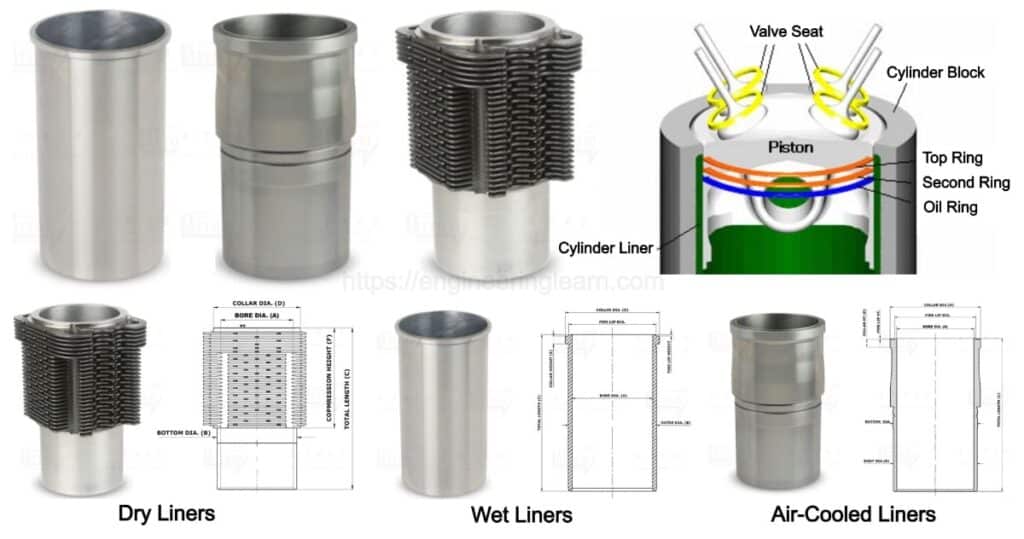

Cylinder Liner Types and Function :- A cylinder liner is basically of a cylindrical shape. It is fitted into the engine block in order to form a cylinder. In the composition of the interior of an engine, the cylinder liner is a very important part. The word cylinder liner is popular in Japan, however in other countries it is also known as Cylinder sleeve. When the motor is operated, there is a considerable amount of wear and tear of the piston. The cylinder liners thereby being the interior metal component saves considerable amount of wear and tear of the piston. When an engine works, the piston as well as the piston rings slide with great speeds. Due to this there is high pressure and high temperature generated in the cylindrical wall of the engine. Hence, to maintain the longer service life of buses, trucks etc cast iron cylinders are used.

The reason behind using the cast iron cylinders is that they have brilliant wer- resisting properties and hence they prove to be very efficient when used for cylinder parts. However, in the recent times Aluminum alloys are gaining widespread popularity due to its light weight. Lighter engines are now preferred over the heavy engines. But the aluminum alloy cylinder suffers with the demerit of deformation during operation when the direct sliding motion of the piston and the piston rings take place. Also it has poor wear-resistance. For this reason, the cast iron cylinders are still not out of fashion and are used especially for heavy automobiles.

Function of Cylinder Liners

A cylinder liner is the central working part of a reciprocating engine or pump, the space in which a piston travels. Problem of the cylinder wear is considerable and this has been solved by the use of cylinder liners. The cylinder liners are in the form of barrels made of special alloy iron containing silicon, manganese, nickel and chromium. They are centrifugally casted. Now a day’s cylinder liners are fitted on the engines of cars and commercial vehicles. These liners are of oil hardening type and offer considerably longer life for the engine.

1. Formation of Sliding Surface

The major function of a cylinder liner is forming a sliding surface for the piston rings. It serves as the inner wall of a cylinder. It also retains the lubricant within itself. Also it’s another most important function is the excellent characteristic as sliding surface and these four necessary points.

•It has high anti-galling properties

• There is less wear on the cylinder liner itself

• There is less wear on the partner piston ring

• There is less consumption of lubricant

2. Heat Transfer

The cylinder liner transmits the heat to the coolant .It receives the heat from the combustion through the piston and piston rings.

3. Compression Gas Sealing

The compressed gas as well as the combustion gas is prevented from escaping by the compression gas sealing.

Types of Cylinder Liners

Cylinder Liner Types and Function: There are basically three different types of cylinder liners namely, Dry, wet and finned. Each and every type of cylinder liner uses slightly different method to work. However, the basic principle remains the same that is to protect the piston from heat and impurities. The cylinder liners are specially designed products. They are expensive and requires precise manufacturing. Hence they are only available at special motor parts.

1. Dry Liners

The dry liner is made in the shape of barrel having a flange at the top which keeps it into position in the cylinder block. The entire outer surface of the dry liners bears against the cylinder block casting and hence has to be machined very accurately from outside also. Thus, it is not in direct contact with the cooling water and hence is known as dry liners. Its thickness ranges from 1.5 mm to 3 mm. It is used mostly for reconditioning worn cylinders.

2. Wet Liners (Water Cooled Liners)

A wet liner makes up a complete cylinder barrel. It is provided with the flange at the top which fits into the groove in the cylinder block. At the bottom of the block or the liner is provided with grooves, generally three in numbers, in which the packing rings made of rubber are inserted. The liner is in direct contact with the cooling water hence it is known as wet liner. The outer surface of the wet liner does not require accurate machining. Headliners article than dry liners as they range from 1.5 mm to 6 mm.

Advantages of wet liners over dry liners

- A wet liner can be replaced easily and for this purpose there is no need of any special tool or equipment.

- A wet liner reduces the temperature of the piston by being in direct contact with circulating water.

- A wet liner has to be provided a leak proof joint between the cylinder casting and the liner whereas there is no such requirement of dry liner.

- A wet liner is free to expand without any resistance since it is held by a flange only at the top.

- A wet liner required simple construction of cylinder block without any accurate machining on the inside surface of cylinder block.

- A wet liner can be finished accurately before fitting, whereas a dry liner cannot be finished accurately before fitting because of the shrinkage stresses produced.

3. Finned Cylinder Liners (Air-Cooled Liners)

Heat and impurity resistant metal is used for the construction of finned cylinder liners. Primarily designed for the air-cooled engines, the finned cylinder liners works pretty much the same as dry cylinder liners. Fitted with tiny fins in order to allow the air which is flowing in to draw with a great force to achieve cooling of the cylinder.