Needle Valve: Definition, Types, Function & Application

What is a Needle Valve?

Needle Valve: Definition, Types, Function & Application :- Needle valves, also called plunger valve sometime, are the pressure and flow regulating valves which helps to accurately control the pressure and flow rate of a fluid flowing inside the pipeline. The adjustment or actuation processes of needle valves are so fine that it gives the extremely precise control over the fluid flow. These valves are generally used for low flow rate and high pressure drop from inlet to outlet application.

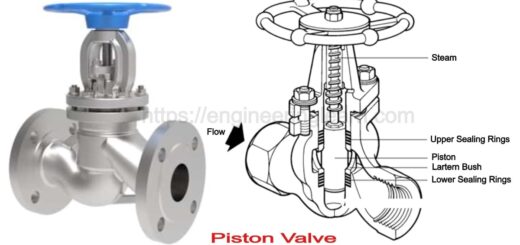

However, they can also be used to cut-off or shut down the fluid flow in the pipeline. Its working mechanism is more or less similar to the piston check valves except the size of piston used in needle valve is thinner in comparison. In the figure the different parts of a generalized needle valve is labelled.

Function of Needle Valve

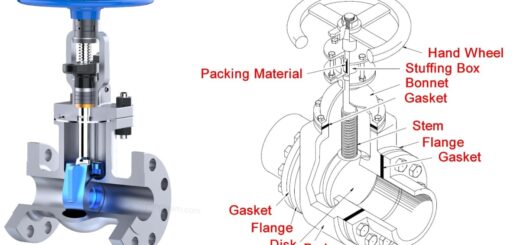

The needle valve opens and closes the passage (orifice) between inlet and outlet by the movement of tapered point needle normal to the flow direction. The needle is directly connected to the plunger or stem. The stem is further connected to the handle which converts the rotary motion into to and fro motion by the help of fine internal thread of the bonnet.

As the rotary motion given to the handle the fine up-down movement plunger takes place which subsequently opens or closes the orifice. The locking nut is also attached at the top of the bonnet which prevents the complete unscrewing of the plunger from the bonnet’s internal thread. As the needle goes down it comes in contact to the valve seat and hence provides a leak proof shut-off of the fluid in the pipeline. The bonnet is connected to the valve housing through a screw system.

The actuation of the valve is controlled either by manual rotation of the handle or by automatic. The automated needle valves are generally operated either by electric motor or by hydraulically. The motor or hydraulic actuator precisely controls the position of stem inside the valve housing (bonnet) according to the external requirement.

Applications of Needle Valve

The most common use of needle valves is to regulate the flow and protect fragile gauges from any harm caused by abrupt pressure surges of liquids and gases. Needle valves are perfect for systems using lighter and less viscous materials with small flow rates. Needle valves are usually employed in low-pressure hydraulic systems, chemical processing, and other gas and liquid services.

Another specialty of needle valves is that they can also be applied to elevated-temperature and oxygen service based on their materials. Needle valves are generally made of stainless steel, bronze, brass, or metal alloys. It’s mandatory to opt for a needle valve made with the material that perfectly suits for the service you need. This way one can ensure longer service life of the valve and keep the systems running smoothly and safely

Selection Criteria of Needle Valve

The needle valves can be selected on the basis of four main criteria; material, pressure, port & orifice size and temperature. The most common material used for the manufacturing of the needle valve is stainless steel and brass. The brass valves are suitable for the non-corrosive applications such as potable water flow system. Whereas, the stainless steel valves are generally used for high corrosive media such as seawater, acids etc. however, both of the material can handle the high temperature of fluid but the stainless steel valves are superior to brass needle valves in terms of durability and corrosion resistance.