Types of Hydraulic Valves

What are Hydraulic Valve?

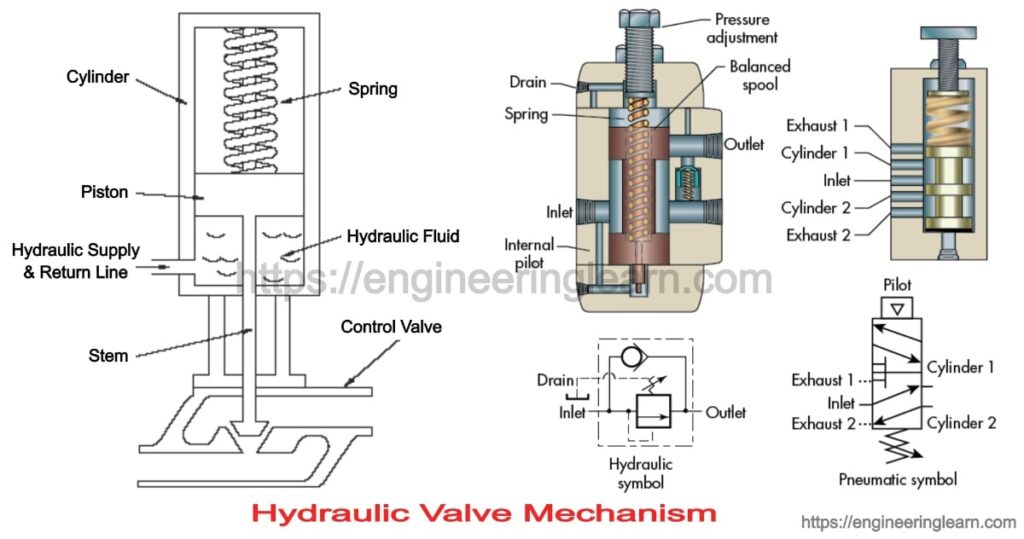

Types of Hydraulic Valves : Working, Uses, Mechanism, Applications : Hydraulic valves are defined as the mechanical devices which are used to control and regulate the flow of a fluid in hydraulic system, and the direction of flow can be determined by position of the spool. They can be used for completely closing the line in which the fluid is flowing or to redirect the flowing fluid or just to control the level of fluid flowing in a certain area.

They are designed in various styles and they can be controlled mechanically, pneumatically, by hydraulic means, by electric means or manually. These are capable of sustaining high pressure fluids and the pressure of few hydraulic systems can go to as high as 3000 psi. This is why these valves are constructed of iron, steel and other metals which have high strength under pressurized condition operation.

The selection of the valve is done as per the requirements while the size of valve is determined by the maximum flow of fluid in hydraulic system through valve and the maximum system pressure.

Uses of Hydraulic Valves

- Hydraulic valves regulate the flow of fluid through hydraulic systems

- It can be used to switch to required pressure

- It can regulate or restrict the direction of fluid flow

Types of Hydraulic Valves

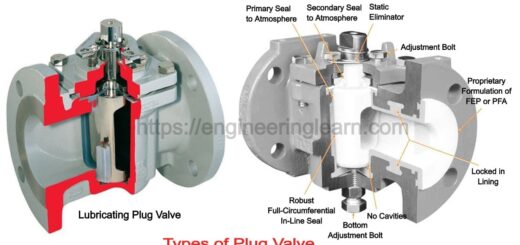

Hydraulic valves are of various types such as butterfly valve, check valve, relief valve, ball valve, bypass valve, needle valve, regulating valve, diverted. All these types are further classified into three major sub categories, namely:

1. Hydraulic Pressure Control Valves

These valves are used to control and regulate the pressure of fluid which is passing in a Hydraulic system and maintain the required set pressure. The main purpose of providing this valve is to avoid the pressure rise which results in leakage of hydraulic fluid and bursting of pipes. They are also helpful in maintaining a set pressure. In hydraulic systems, there are various types of valve used for pressure controlling operations such as relief valves, counterbalance valves, sequence valves, reducing valves etc.

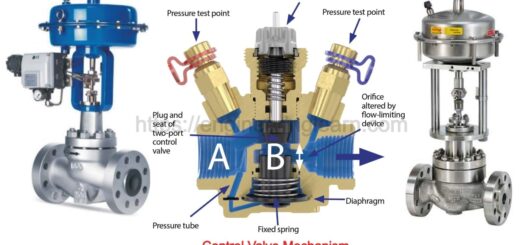

2. Hydraulic Flow Control Valves

These types of valves are used to control or regulate the flow rate of a hydraulic fluid in a hydraulic system. These valves have adjustable ports which enable them in changing the area of flow which results in change in flow rate through valve. Flow rate in these valves is directly related to the speed of the valves. When the flow rate is reduced then the speed at which the valve is operating is also reduced and vice versa.

The various types of hydraulic control valves are adjustable flow control valve, fixed flow control valves, pressure compensated flow control valves and throttling flow control valves. The method of flow control in these valves varies according to their mechanical design. Flow rate of the fluid can be measured in different ways also. Hence, the selection of suitable types of valves is done on the basis of understanding the flow rate.

Common Types of Hydraulic Control Valves are:

- Deceleration valves

- Priority valves

- Pressure compensated, variable flow valves

- Pressure – temperature compensated, variable flow valves

- Proportional flow control logic valves

- Pressure compensated proportional flow control valves

3. Hydraulic Directional Control Valves

Hydraulic directional control valves are used to regulate the direction of hydraulic fluid in a hydraulic system to different devices according to requirement. They can be used for shifting intermediate state wherein they can control the direction, acceleration or speed of an actuator. A binary valve is simple example of hydraulic directional control valve which can restrict or pass fluid flow.