Types of Threads: Definition, Parts and Thread Identifying Tools [with Images]

![Types of Threads: Definition, Parts and Thread Identifying Tools [with Images]](https://engineeringlearn.com/wp-content/uploads/2021/06/Threads-1024x539.jpg)

Definition of Threads

Types of Threads: Definition, Parts and Thread Identifying Tools [with Images] :- Thread are found having a very critical role in the engineering line specifically for manufacturing various items of day to day life. In the manufacturing industry the machines are used almost at every moment and without threads, almost all the machines are incomplete. Talking in the technical language the spiral grooves of equal measurement or shapes made up of a round cylindrical article or pipe are referred to as threads or in other words, spiral grooves of equal pitch and equal depth which is made on the parallel round cylindrical surface or conical round surface is referred to as threads.

Main Parts of Threads

Generally there are three main parts of the threads are following:

- Shank Diameter

- Thread Per Inch ( TPI)

- To The Point

1. Shank Diameter

Shank diameter is represented by the diameter of the thread as the number goes higher so as the diameter of the threads. Shank size will decide which screw threads is most compatible or ideal with for the specific job.

2. Thread Per Inch ( TPI)

It is generally abbreviated as TPI. This is simply the no of threads found or designed in an inch (1”). Low TPI likes of 7 &8 represent the coarse screw while 18 or 22 provides the fine screw threads for metal fastening.

3. To The Point

The most common types of screw points are self piercing point & self drilling points.

Self Piercing Point :- it has such sharp point designed to cut through the material as the screw thread.

Self Drilling or Drilling Points :- it is equipped with drilling feature at the tip of the screw that is used to bore a hole through the metal before thread engages to fasten the pieces together.

How to Identify Different Types of

Threads?

Before you start, make sure you have two thread identifying tools on hand;

1. Pitch Gauge

A pitch gauge is referred to as an instrument which is used to measure the distance within the crests of threads. For NPT, UN/UNF, BSPP and BSPP the number of threads per inch are measured. In case the observer has the metric threads, then the pitch gauge would identify the distance within each individual crest in millimeters.

2. Caliper

A caliper is referred to as that instrument which is used to measure the diameter of a thread. For the male threads, it is found measuring just the outside diameter whereas for the female thread it measures the inside diameter. For all the advanced users, there is a digital caliper which is available in the market which saves the time and also simplifies the process.

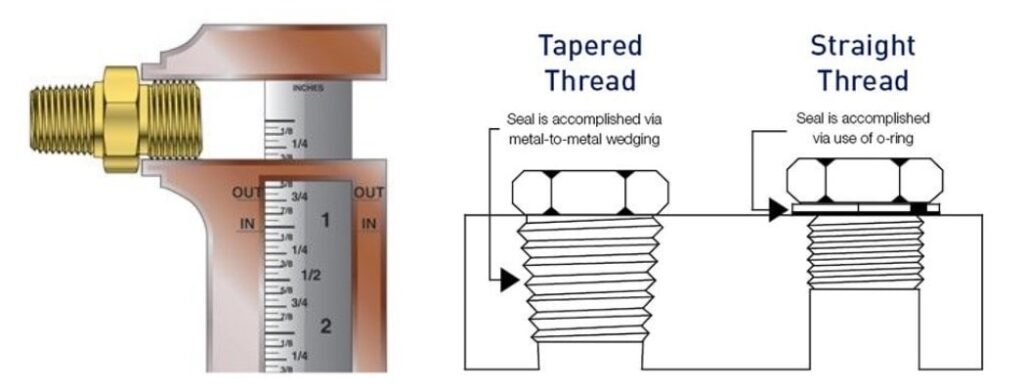

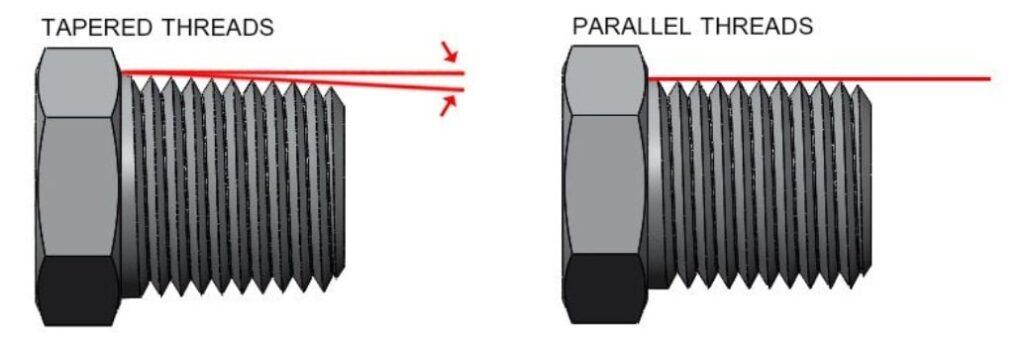

A) Difference Between Tapered Thread & Parallel Thread

There are various types of threads, so it important to know all the types of threads along with their features and applications so that while using these instruments a correct type can be selected by the user. Scroll down to know more about the types of threads.

Parallel threads are the threads which include:

- UN/UNF

- BSPP

- Metric parallel

Tapered threads are the threads which include:

- NPT/NPTF

- BSPT

- Metric tapered

In order to identify whether the thread is tapered or parallel one can have a look at the diameter of the thread. In case the thread diameter is found being thinner towards the end then it is confirmed that it is a tapered thread. Whereas in case the thread diameter is found to be same at the top as well as the bottom of the thread then it can be termed as a parallel thread. There is one more way by which you can find out whether it is a parallel thread or tapered thread, if the threads touch the entire length of the calipers then it is surely a parallel thread otherwise it is a tapered thread.

B) Determine the Size

An instrument known as thread pitch gauge tool should be used in order to determine the size of the thread. The thread pitch gauge helps you in accurately measuring and calculating the number of threads within a required distance.

C) Size of the Thread

Whenever it comes to determine the actual size of the thread one should have two approaches. Before starting one must determine whether your thread is a pipe thread (NPT/NPTF, BSPT, BSPP) or not (UN/UNF, Metric Parallel, Metric Tapered). One must note that the tapered thread can be a pipe thread. In case you are found having pipe thread then you can compare the size of the thread with a nominal size profile. If you are working for non-pipe thread (UN/UNF, Metric Parallel, Metric Tapered) then you must use the caliper tools in order to measure the outside diameter of the thread.

4) Designated Thread

These are the steps which involve a designating thread according to the industry standards for further use. Start with identifying the thread size and then note the type and pitch.

13 Different Types of Threads

While coming to types of threads most of the people who work in the industry can recognize the types of threads as almost all these types are used in the industries. Mainly the threads and connections are divided into six types which are as follows:

- UN/UNF

- NPT/NPTF

- BSPP (BSP, parallel)

- BSPT (BSP, tapered)

- Metric parallel

- Metric tapered