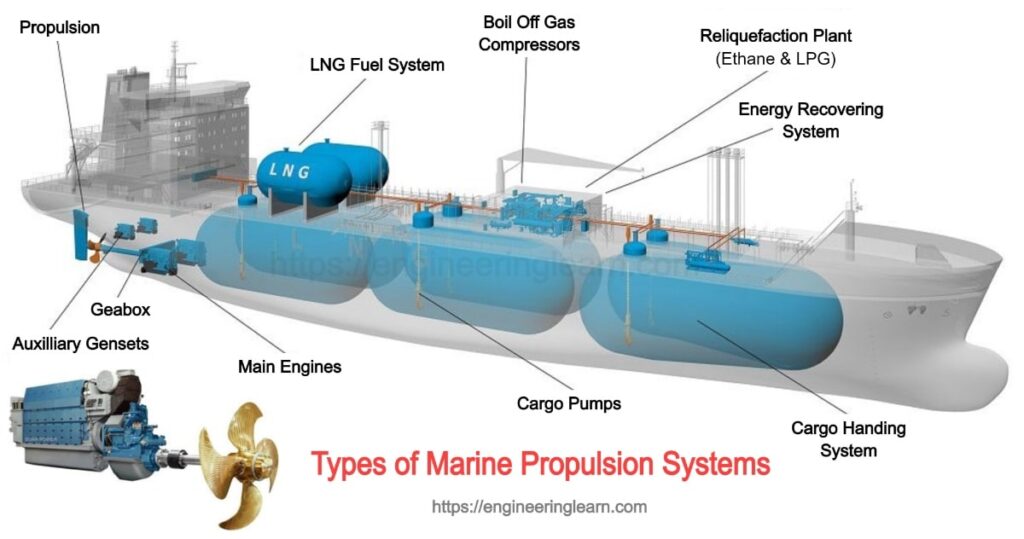

Types of Marine Propulsion Systems

Types of Marine Propulsion Systems :- With the effect of propulsion forces, ships are able to move on their own in the water. In the ancient time there was a limited number of ship propulsion system whereas in the present time there are ships with numerous innovations with the help of which a vessel can be fitted.

In the current scenario ship propulsion is not only about the proper movement of the ship in the water but also includes the best mode of propulsion to make sure better safety standards for the marine ecosystem keeping the cost effectiveness in mind.

Types of Marine Propulsion Systems

Here are some of the different types of propulsion systems which are commonly used in ships and are enumerated as follows:

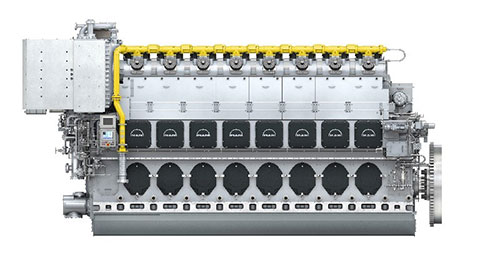

1. Diesel Propulsion Systems

Diesel Propulsion is the most popularly used marine propulsion system which converts the thermal energy into the mechanical energy. These marine propulsion systems are almost used in all types of vessels including small boats and recreational vessels as well.

2. Wind Propulsion Systems

Wind propulsion is an alternative to those systems which discharge Carbon dioxide gases in huge quantities in the atmosphere of water. The usage of wind turbine marine propulsion is not working extensively in huge commercial ships due to the requirement of constant windiness.

In ancient times there were two wind propulsion systems that were used and are known as kite propulsion and sail propulsion.

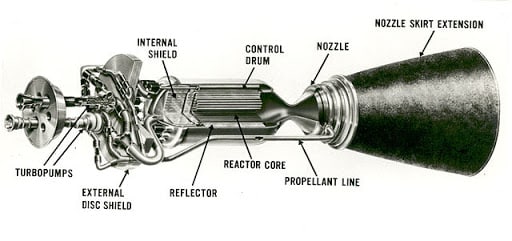

3. Nuclear Propulsion Systems

The battleship includes the usage of nuclear propulsion. Using this nuclear fission process which is a highly complicated system consisting of various water reactors and other accoutrements to fuel the vessel.

The nuclear reactors of the ships are used to generate electricity which is used only for the ship. Various merchant ships are also being designed to be constructed with this propulsion system which has various applications.

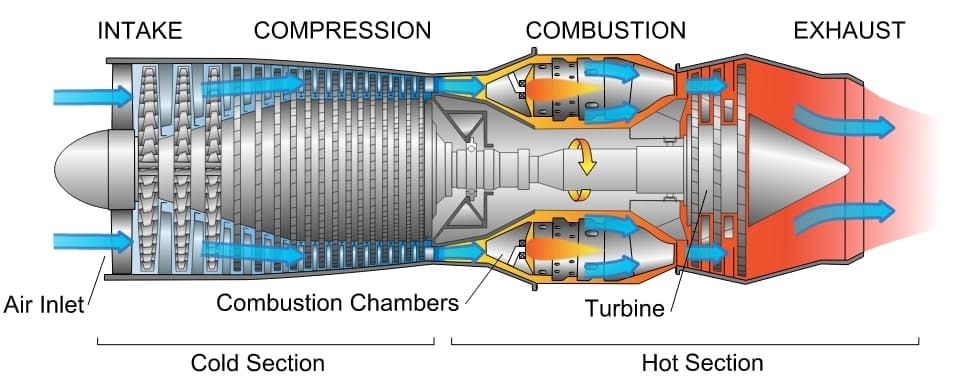

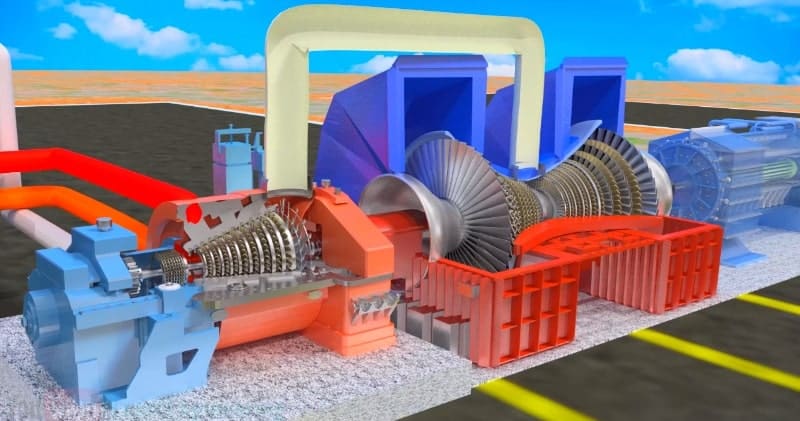

4. Gas Turbine Propulsion

Gas turbine propulsion is mainly used for two different types of ships like naval and non-naval ships. For naval ships, the gas turbine propulsion system initiates in the faster movement of the ships which is very necessary when the ship is coming under attack.

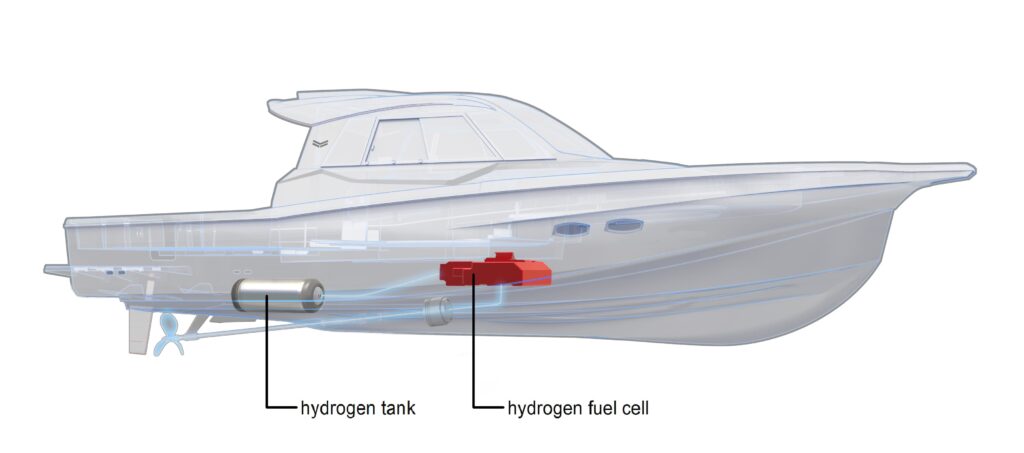

5. Fuel Cell Propulsion

The main fuel component system used in a fuel cell propulsion is hydrogen. The electricity is created without any combustion inside the fuel cell itself. This process of creating electricity is clean and has been regarded as a very critical and alternative marine propulsion system.

There are different types of propulsions beneath the fuel cell propulsion head. For example PEM (Photon Exchange Membrane) and MCS (Molten Carbonate Systems).

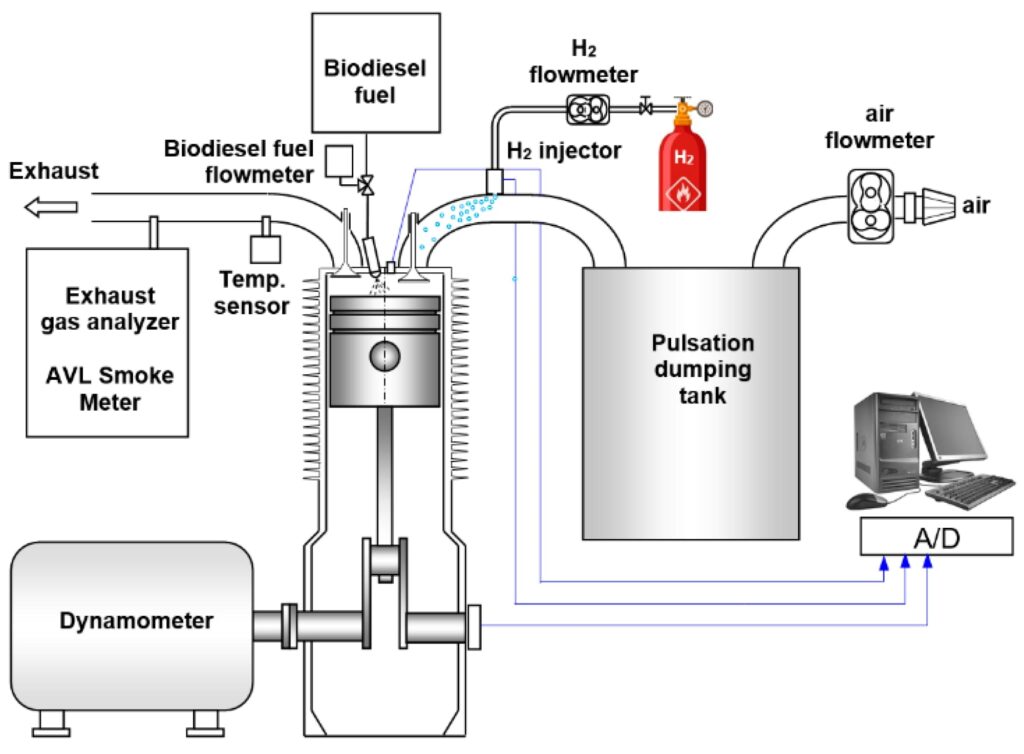

6. Biodiesel Fuel Propulsion

Biodiesel propulsion is considered as a potential marine propulsion system of the near future. In the present scenario there are tests being carried out to find out the viability of the propulsion system which is expected to have full operation soon.

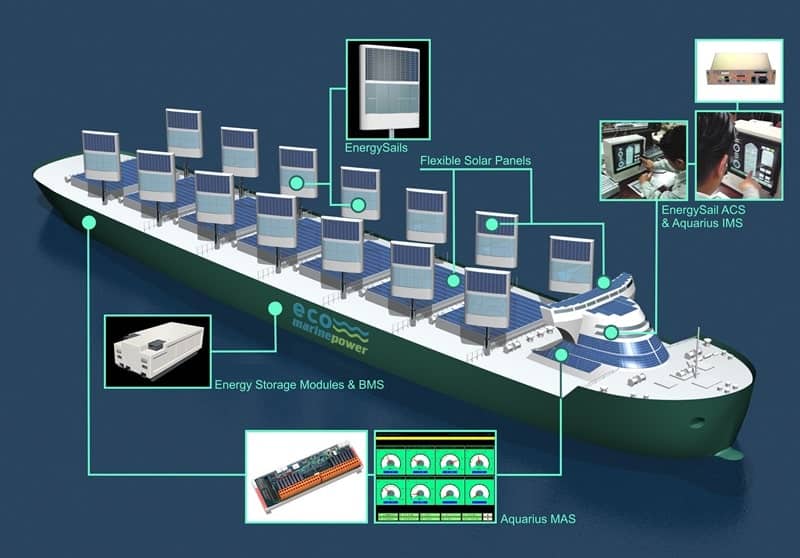

7. Solar Propulsion

Solar propulsion for ships was first initialized in the year 2008.The main advantage of solar propulsion is that it reduces the emission of poisonous carbon dioxide in the atmosphere of water. Solar propulsions are capable of creating a capacity as high as 40 kilowatts (kW) which is a quite huge quantity.

8. Steam Turbine Propulsion

Steam turbine propulsion works with the usage of coal and other steam-generating fuels to keep the vessel in motion. Steam turbine propulsion system was mostly used from the late 19th till the early 20th century.

9. Diesel Electric Propulsion

In simple words, diesel-electric propulsion system works with the combination of electric generator which is further attached to the diesel motor. This technology is into being since the early 19th century. In the current scenario, submarines and merchant ships inculcate the diesel-electric propulsion system to propel on their own without being dependent.

10. Water Jet Propulsion

Water-jet propulsion is into being from the year 1954. The most advantageous thing of this propulsion is that it does not cause noise pollution and also offers a very high speed to the vessels on the same time. In other words, the water-jet propulsion is costlier to maintain which is found having problems to its users.

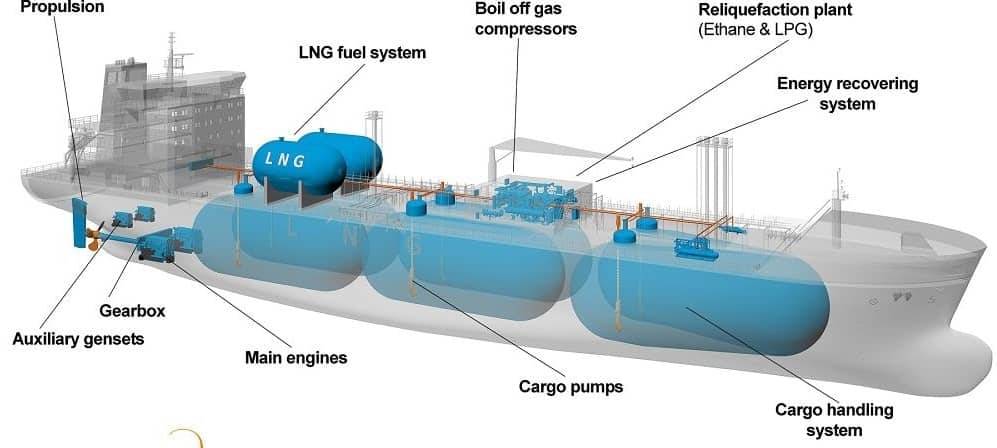

11. Gas fuel or Tri Fuel Propulsion

The fuel utilised to be burnt in the main engine is LNG, which was brought into action after making many modifications in its propulsion engine to reduce the poisonous emissions from the ship. It is known as tri fuel because it can burn three types of fuels like gas fuels, diesel and heavy fuel.

The different type of propulsion system offers its own unique advantages depending upon the requirement and necessity. The best type of ship propulsion system needs to be fitted then only the vessel will be capable to offer the optimum service capacitance.

Repair and Maintenance

Coming to the next is the maintenance and repair of the machinery. So, here are some of the basic components which one should include in their marine maintenance checklist to keep their vessel well-functioning and to keep away from the technical problems.

One of the most important component of marine maintenance is to ensure that the vessel is properly lubricated. As if the oil is reduced the friction is increased which leads to a heavy wear and tear of the moving parts.

Also if it is well lubricated it will keep the pistons and cylinders cool and would seal out the contamination and the corrosion. So in order to keep your boat away from all these losses it is suggested to keep your machineries filters well lubricated which will help in the proper functioning of the engine.

Repair and Maintenance

It is also suggested to regularly clean the sea strainers which if not done can cause a failure to the engine. The sea water works as a coolant to the fresh water system of your engine so you need to be sure about the cycle and also it should be kept free from obstructions to keep the temperature of your engine low.

A few other tips include cleaning, if not replacing your impeller, each year. If you boat in freshwater, be sure that your pressure cap is secure and change your antifreeze every other year. Mixing elbows tend to get clogged over time and should be replaced every three years, and be sure to test your thermostat regularly.