Drilling Machines Types & Operation

Drilling Machines Types & Operation :- Drilling is an operation in which hole is created by removing either metal or wood surface with the help of cutting tool known as term Drill.

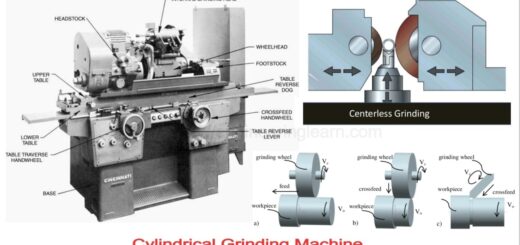

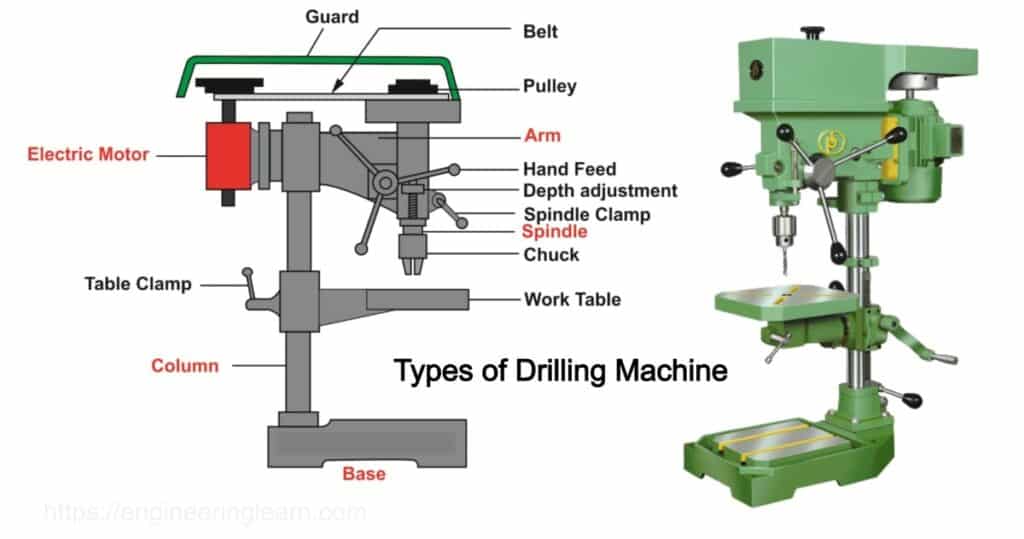

Construction of Drill Machine

Drilling machine mainly consist of following parts are described below: Machine consist of drill that is to be rotational used in operation along its axis of the workpieces which is at rest (stationary position) while some other parts are,

- Drill machine head is equipped with electric motor, for transmission of rotary motion into spindle at some speed via the V-pullers or V belts.

- Material of construction of spindle is alloy steel. It is provided for rotation & mover vertically up- down through the sleeve.

- A pinion with rack arrangement is Constructed to the spindle for movement of position vertically up-down.

- Drill chuck is provided at the end of spindle, to turn & hold the drill bits.

- Adjustable workpieces table is provided for stable & safe operation of drilling machine.

- Base plate having a heavy casing that support structure.

Types of Drilling Machines

Drilling machines of main types are described below:

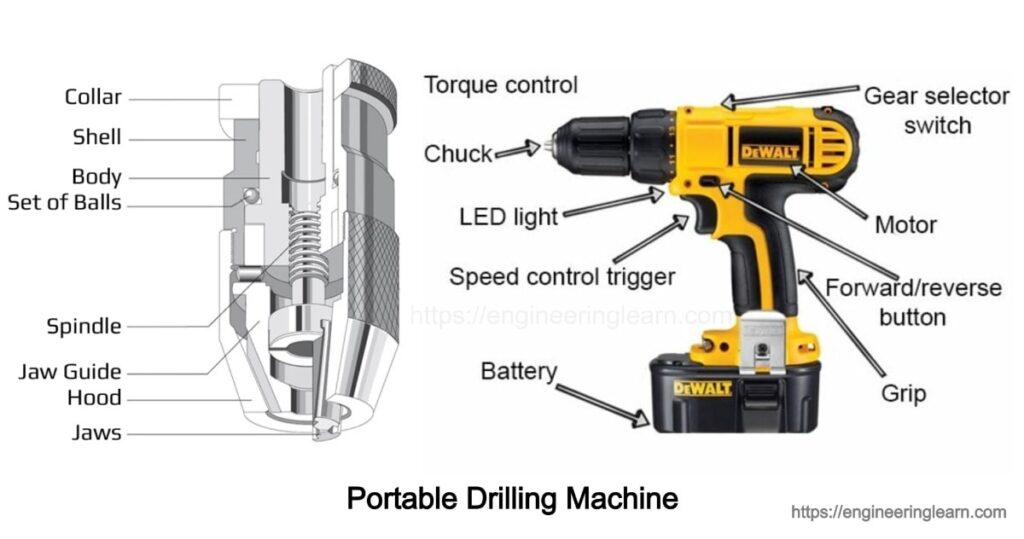

1. Portable Drilling Machine: ( Types of Drilling Machines )

This is known as hand drilling machine. The most common type of machine used by manufacturing company. This is designed for drilling holes into metal, wood or rock etc. This machine is usually smaller in size which makes an advantage for operation at different location sites. It operates with universal type of motor that is having 12-18 mm diameter. These drilling machines are quite efficient with operation abilities at high speed.

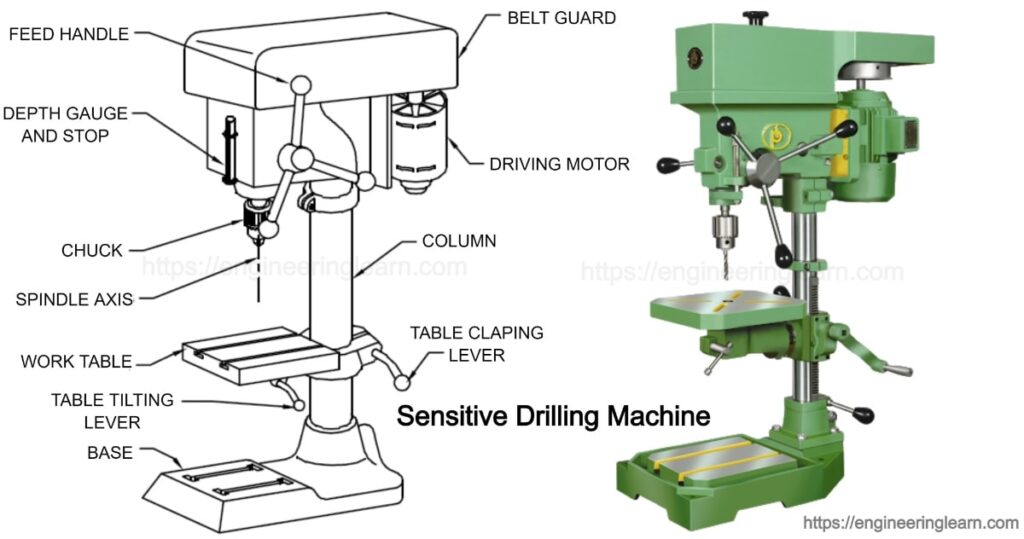

2. Sensitive Drilling Machine: ( Types of Drilling Machines )

These are called as bench drilling machines, they are used to make small holes at high operating speed. It is mounted on the bench with the help of bolts/ nuts can be connected by hand or machine. Sensitive drilling machine are equipped with base, table & spindle.

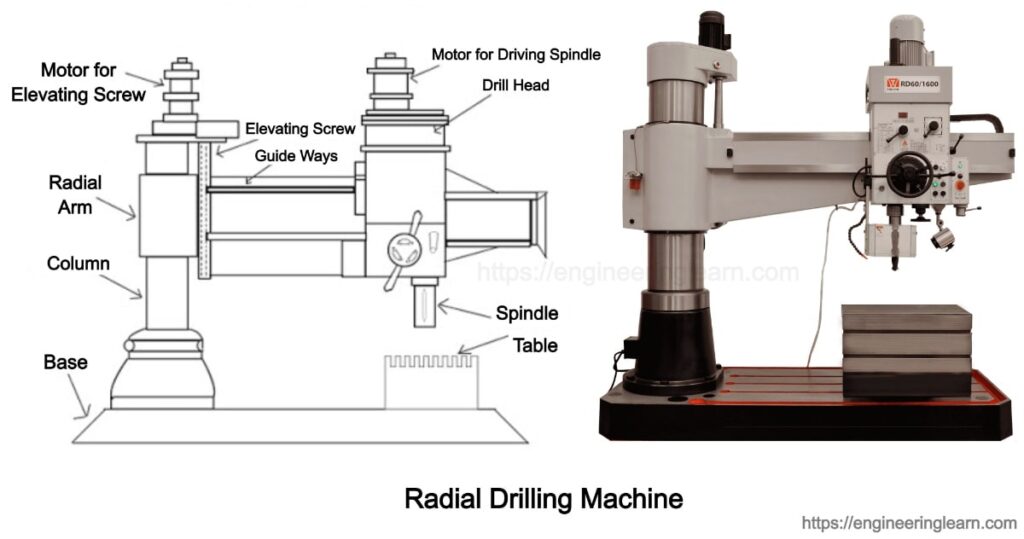

3. Radial Drilling Machine: ( Types of Drilling Machines )

These machines are used for making holes larger & heavy workpieces. As the name suggest it is equipped with radial arm in column which allows moving position vertically up or down for drilling the workpieces of various with respect to their different height. It is also used for rock drilling components that can be use by any company. Radial drill machine operates at driving mechanism of separate & different feed. The position of the machine is adjusted by sliding of drill & gateway of the arm.

4. Gang Drilling Machine: ( Types of Drilling Machines )

This machine having a long table & base structure likes of all other machines. It mainly contain 6 drill head placed side by side. The drill head having separate for their working. These machines are used for drilling, reaming.

5. Deep Mole Drilling Machine: ( Types of Drilling Machines )

This is a special types of drilling machine, designed to drill deep holes in connecting rods, spindle, as well as barrels of gun. These machines are ideal for creating deep holes achieved at high operating cutting speed & less feed & coolant to be used during the process.

While some other types of machine are :

- Multiple spindle drilling machine.

- Upright drilling machine.