Types of Puller

Types of Puller :- A puller is a tool used to remove sets from the rotating machine shaft. The most common application of puller is removing a caped set of ball or tapered bearing from a rotating shaft. For example In car transmission pullers are made up of steel of tool grade. While tool grade is harder than the parts they are used on.

Generally these pullers are hand powered with a handle to turn the screw. Some are powered hydraulically using hydraulic power piston to press against the end of shaft the bearing is on.

These pullers are also comes within small variety in sizes to remove the (mm) size bearing. These are arms with extension that gives slight edge to user for pulling bearing easily during the operation.

Main components of puller

Some main parts of the pullers assembly are listed below:

- Hexagonal head on bearing puller – hexagonal head is attached to the forcing screw. It is fixed with socket wrench for rotation with ease.

- Bearing puller forcing screw – forcing screw is long & fine threaded screw that is rotated corresponding to the shaft. When they force is applied to the screw to produce force that is transmitting to the components that we are removing.

- Bearing pullers cross arms – the cross arms attaches the legs to forcing screw.

- Reversible claw legs on a bearing pullers – legs allows internal & external pulls.

Types of puller

These pullers include bearing splitter plates, 2 and 3 arms bearing pullers, internal bearing pullers, bar type puller &slide hammer puller.

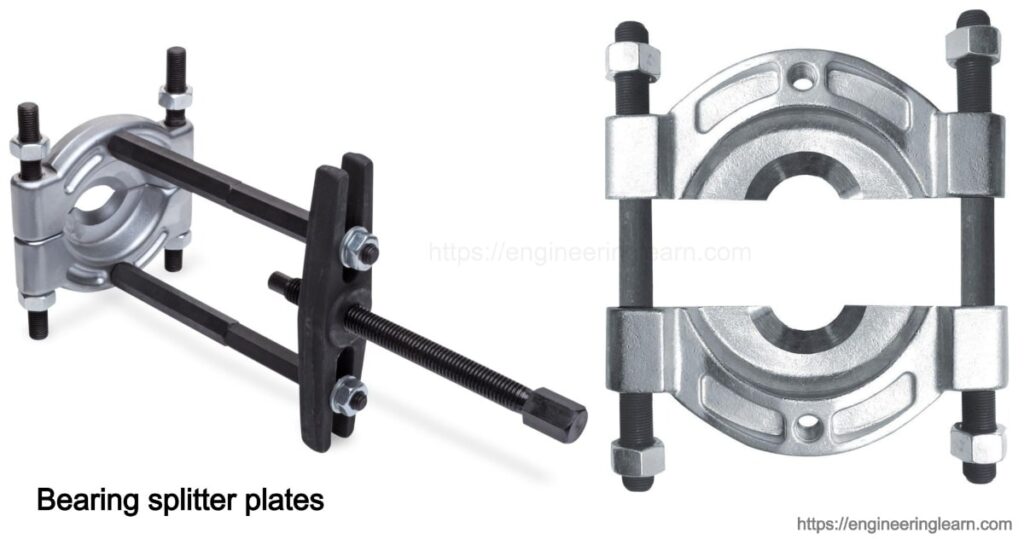

1. Bearing splitter plates

Bearing splitter plates are safest types of bearing pullers to use. From technically point of view they are actually not puller as they uses the mechanism of pushers, they tends to push and pop ( meet or fixed) with the shaft.

Bearing splitters plates mainly consist of two plates held together with respective to their large diameter, heavy nut with good duty screwed with the help of nut on the all 4 ends.

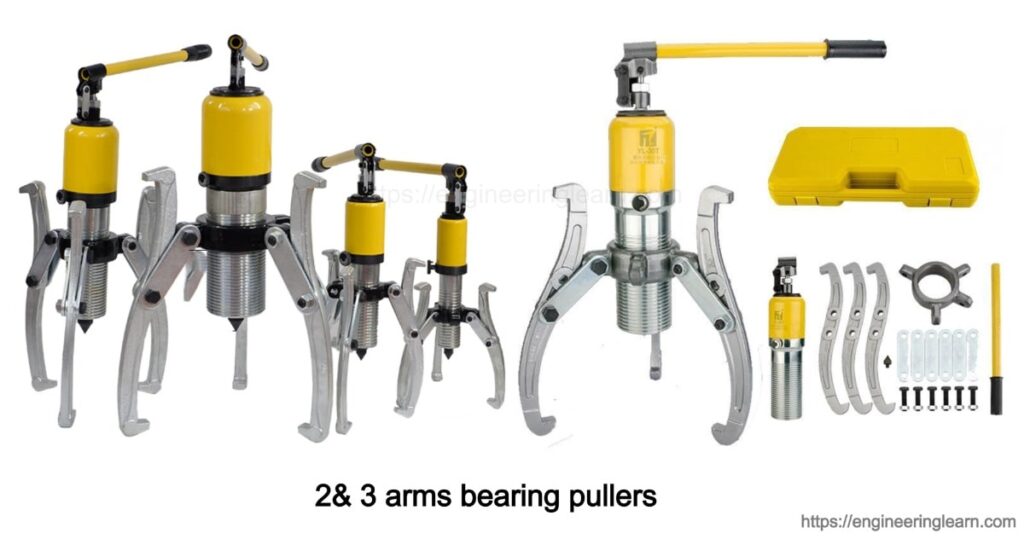

2. 2& 3 arms bearing puller

These are one of the most common types of pullers to extract (removal) of bearing sets or gears. Arms having fingers on the end that bend to get behind the bearing. The center screw of the puller is torqued so it pushes on to the top of shaft & upward thrust is applied to the bearing. Arms and fingers are reversible so same puller can accommodate the wide variety of bearing & shaft sizes, length.

3. Internal bearing puller

Internal bearing pullers are made up to extract bearing set. These are generally favorable in condition of small dent puller. They have a slide hammer with shaft to act thrust upward &shock to the bearing. Collet is the part that went into the bearing at the tip of puller shaft is expandable.

4. Bar type puller with bearing separator

Bar type with side rod threaded into bearing separator provides knife edge to get behind components or when there is not good gripping edge at all.