Types of Power Hammers: Functions & Uses

What is forging Power Hammers?

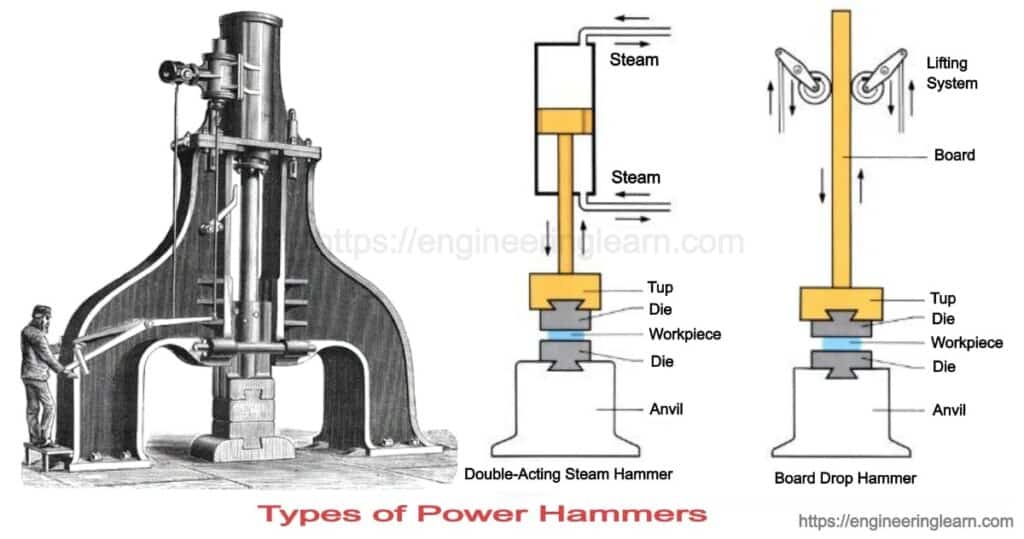

Types of Power Hammers: Applications, Operation & Uses :- The power hammers are the mechanical devices which are also known as forging power hammers which depends on steam in order to create pressure. The latest version of such hammers come with either a pneumatic or an electric hammer. In the layman’s language it can be said that the hammer works when the force is applied in the opposite direction of the rapid movement wherever the object is held.

These mechanical devices uses some or the other type of pressure which is responsible for creating force. The strike is quite faster and is hit with greater force as compared to the force of a hydraulic press. Considering the size of any hydraulic press the power hammers are also quite large in size as compared to the other tools.

The higher the amount of force, the larger would be the required result. The machinery and old models can occupy more space wherever it is supposed to be placed. These are preferred in order to produce smoother as well as uniform outcomes as the sheer mass of the device receives the required vibrations and movements through weight. Here are some of the main types of hammers along with its applications. Scroll down to learn more.

Types of Power Hammers

There are various different types of forging power hammers which are widely used in the market.

- Pneumatic Hammers

- Steam or Air Hammers

- Helve Hammers

- Hydraulic Power Hammer

- Lever-Spring Hammers

1. Pneumatic Power Hammer: ( Types of Power Hammers )

Pneumatic power hammers are quite typical form of mechanical devices which is responsible for carrying the cylinder in which the piston works. This piston is found to be connected to the main motor shaft by the help of a crank and a connecting rod mechanism. A hand lever is also involved which operates the air valve. The air valve is provided through the different cylinders. Another piston also works inside the cylinder which carries the tup at its bottom and is made to slide fixed guides. In order to make the tup move, the piston in the cylinder is moved downwards in order to create the vacuum above the piston inside the other cylinder. This is responsible for providing a suction effect on the piston due to which the tup starts lifting.

Near the end of an upward stroke of the piston, in-cylinder, the air is forced from one cylinder to another where the air is compressed due to the upward stroke of the piston. This is responsible for forcing the piston and thus moving the tup downwards with high velocity. This operation is repeated on regular basis and the required blows are obtained.

2. Steam or Air Power Hammer: ( Types of Power Hammers )

A steam-power hammer is referred to as those which can be performed by the effect of either steam or compressed air. These are the device which includes a moving ram, rod, piston, a lifting tool, a double-acting high-pressure steam cylinder, housing or frame and anvil. These are the forging power hammers wherein the steam gets entered initially and then at the bottom of the cylinder, the piston gets lifted upwards along with the other moving parts. The amount of force is considered as 3m/sec whereas the mass of the moving parts is nearly 5000kg.

Whenever the blow is required, the lever gets energized automatically where the top sliding value is opened in order to receive the steam from the above of the cylinder and the exhaust steam which remains on the bottom. Thus the required blows are obtained.

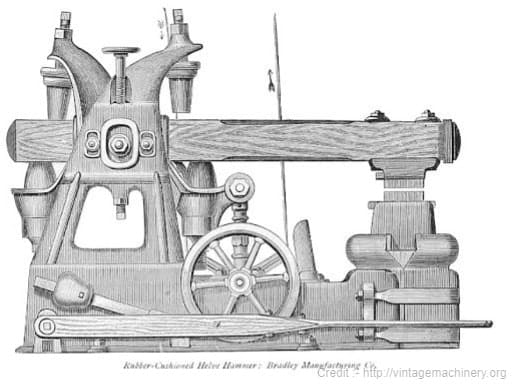

3. Helve Power Hammer: ( Types of Power Hammers )

A helve power hammer is also referred to as a trip or tilt power hammer which is a huge powered hammer. These are the types of forging power hammers wherein more than one helve hammer is installed in a forge which is also referred to as a hammer mill. These forging power hammers are normally lifted with a cam which is suddenly released to drop the force of gravity. The helve hammers are the mechanical devices which are mostly hydraulically driven by a water wheel.

Also, these are used in order to make blooms, made of iron into a more workable bar iron in the finery forges. Other than this, they are also employed in order to fabricate different articles of wrought iron, latten (brass), steel and various other metals.

4. Hydraulic Power Hammer: ( Types of Power Hammers )

The hydraulic hammers is also termed as hydraulic presses which uses 200 to 300 times higher oil pressure as compared to the atmospheric pressure in a hydraulic cylinder. The hydraulic presses are applied in heavy forgings which consists of a press and a hydraulic drive. The rate of production in hydraulic presses is observed to be faster as compared to the other hammer forgings through which the single squeezing action is completed.