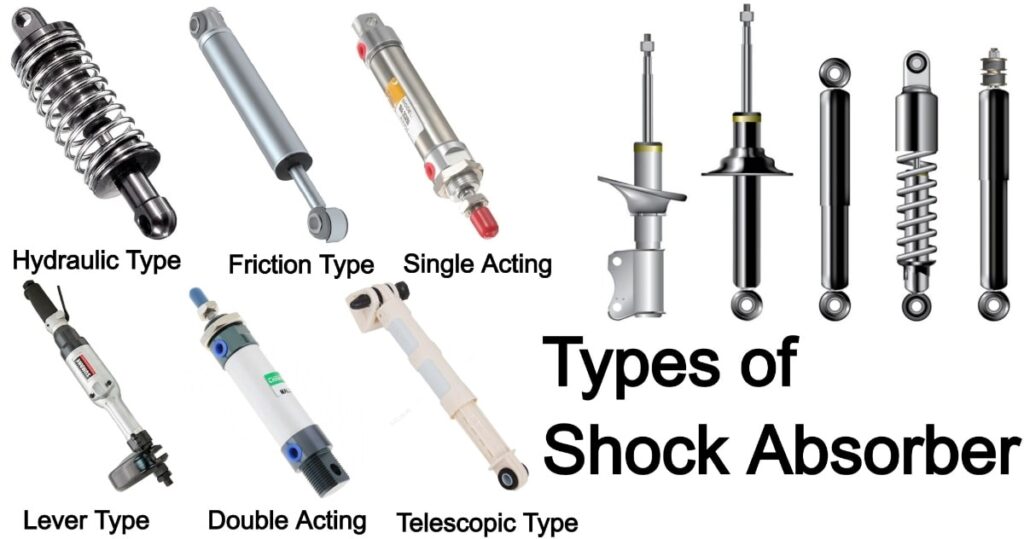

Types of Shock Absorber

Types of Shock Absorber :- Shock absorber is mechanical device used absorbing the energy of sudden impulses or shock in machinery or Structure.

COMPONENTS OF SHOCK ABSORBER

- Shock absorbers are different in design & operation while the main parts remain similar. Some parts of the shock absorber are following:

- Valves, coupler, valve springs, piston.

1. Shock Absorber Mount

Absorber mounts are used to secure shocks to the mechanical body and suspension. It may be upper or lower mount.

2. Shock Absorber Brush

Shock absorbers brushes are located usually located on the mounting. Absorber brushes are made up of rubber or urethane. Absorber brush absorbs the vibration & separates metal parts to prevent noise & wear

3. Shock Absorber Coil Springs

Coil spring works as part of shock absorber assembly also known as coil over shock absorber.

4. Shock Absorber Piston & Piston Rod

Shock absorber piston rod contains valves or openings. Piston rod part guides the piston inside the shock absorber Cylinder

5. Shock Absorber Cylinder

Shock absorber cylinder is the tube that forms body of shock absorber. It mainly contains the compression oil & forms the tube inside the shocks absorber piston moves.

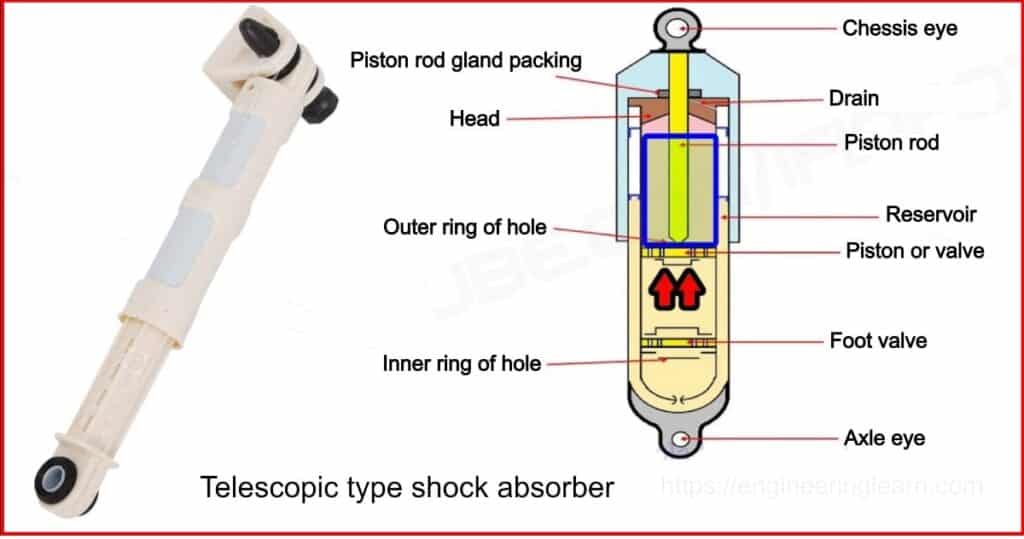

Construction of Telescopic Type Shock Absorbers

Upper eye is attached to the axle and lower to the chassis frame. A two way valve is attached to rod another 2 way valves is connected to lower end of cylinder.

WORKING PROCESS

- when the vehicle came under any bump the lower eye opens up. Therefore the fluid from the lower side valves passes through to upper side but the volume of the space above valve is less than the volume of the rod, the fluid exerts the pressure on is another valve the . The pressure of the fluid valves opening gives the damping forces. Thus when the lower eye moves the down, the fluid passes from the upper side of the valves to lower side & vice versa.

Shock absorber must be filled with shock absorber fluid at regular intervals as recommended by manufacture. When required by its condition. The modern telescopic shock absorbers are no longer serviced. If they leak or don’t offer proper resistance to push and pull they should be replaced.

TYPES OF SHOCK ABSORBERS

Few important types of shock absorber are following:

- Hydraulic type

- Double acting

- Single acting

- Friction type

- Lever type

- Telescopic types

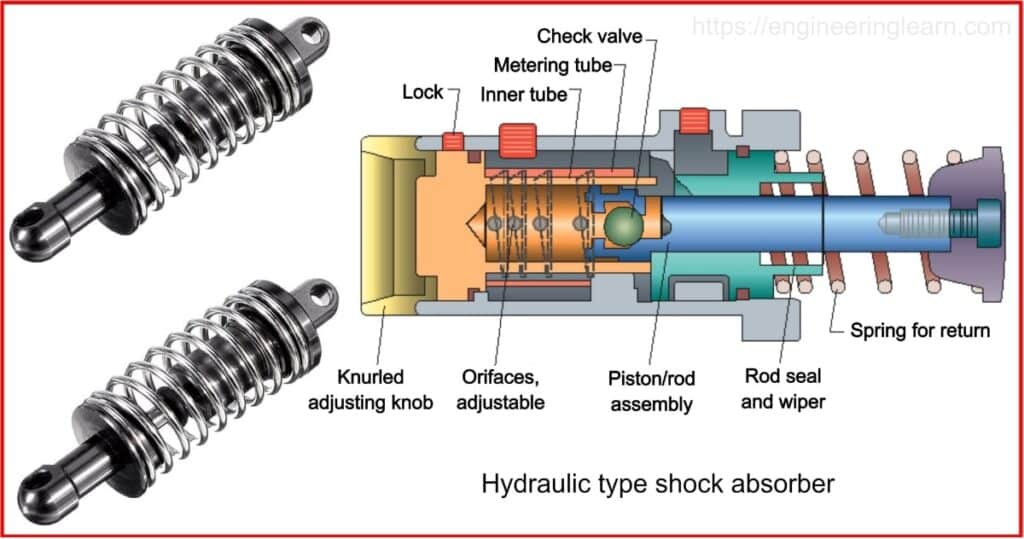

1. Hydraulic Type Shock Absorber

These are mostly used in passenger cars. They are highly resistance to the spring action by forcing a fluid through check valves & small holes. They work on following principle as converting kinetic energy into the thermal (heat) energy. Fluid inside the shock absorber is flown through the outlet & valve system whenever force applies to produce hydraulic resistance.

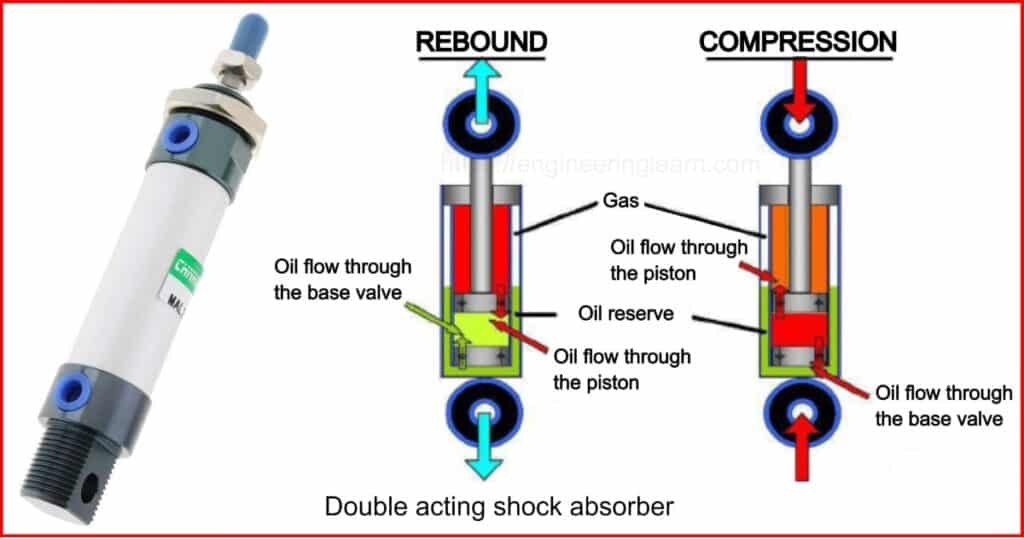

2. Double Acting Shock Absorbers

Double acting shock absorber offers resistance both during compression and rebound holes. They usually used on modern vehicles; it has capability of use of highly flexible springs.

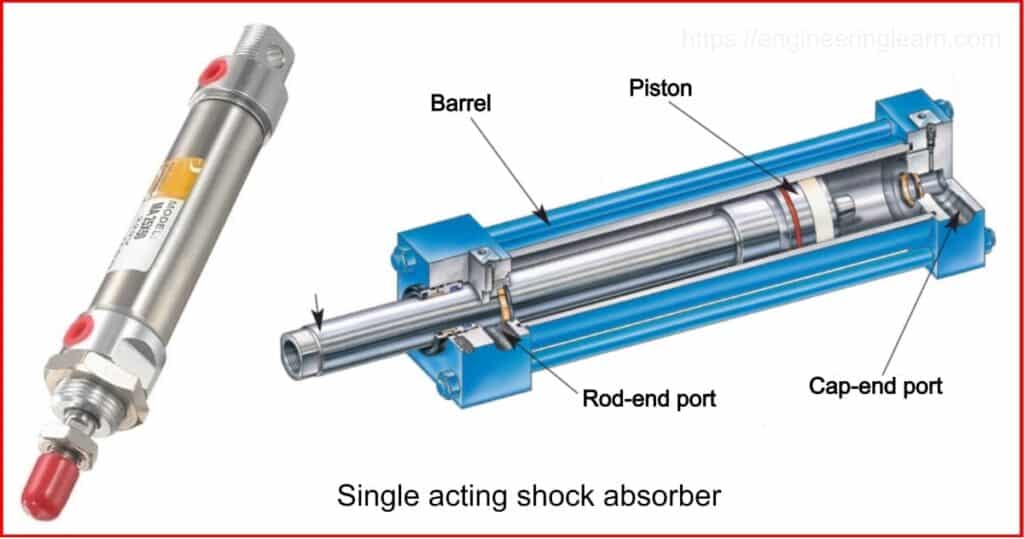

3. Single Acting Shock Absorbers

They only produce the resistance only at the rebounding stage during operation.

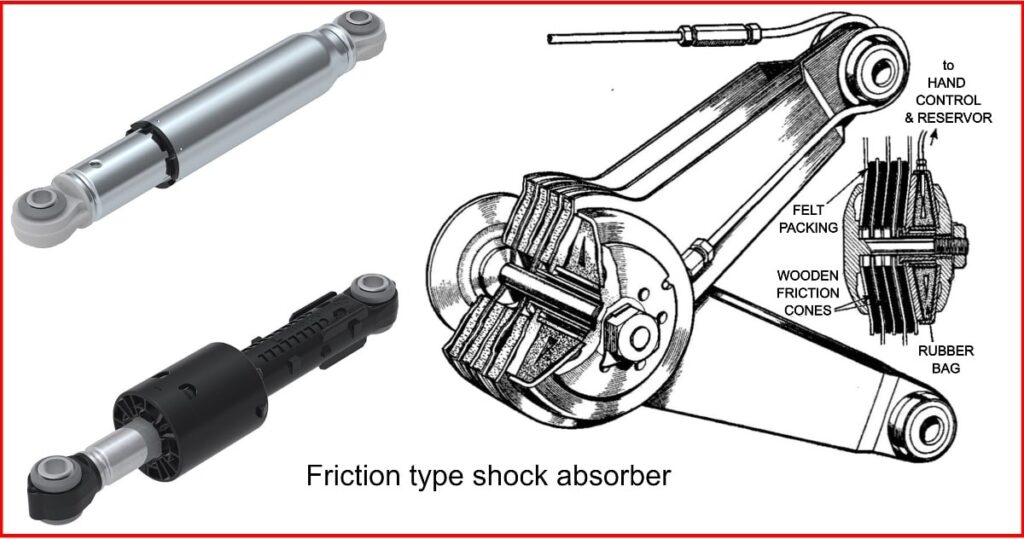

4. Friction Type Shock Absorber

Friction type shock absorber have been almost outmoded (old fashioned) because of its non predictability of damping characteristics property.

5. Lever Type Shock Absorber

Lever types are of indirect type. They are made up of using bolted to the chassis through a lever and link. As the axle moves up & down, a double piston arrangement forces oil through valve. They are used in car suspension device that uses hydraulic oil, the resistance forces enhance with increase in speed. This gives better damping characteristics for longer suspension bumps.

6. Telescopic Type Shock Absorber

Telescopic types are of direct type. Basically it is mounted between the axle and the frame. They can be compressed or extended. They are subdivided in bi-tube or twin tube damper.

Image Source :- Motordynasty, Researchgate, Wikimedia, Howacarworks