Types of Plug Valve: Parts, Uses, Working Principle, Applications, Advantages & Disadvantages

What is a Plug Valve?

Types of Plug Valve: Parts, Uses, Working Principle, Applications, Advantages & Disadvantages :- Plug valve can be defined as basically a quarter-turn rotary motion valve that employs a narrowed or cylindrical plug to obstruct or open the flow. The disk has a plug outline, which has an opening to pass the flow.

In the unfastened arrangement, this bored passage is in line with the flow. When the plug is rotated 90 degrees from the unfastened arrangement, the solid part of the plug hinders the flow. The plug valve is used in place of a gate valve where the fast operation is needed. This valve can also be used in high-pressure temperature services.

Types of Plug Valves

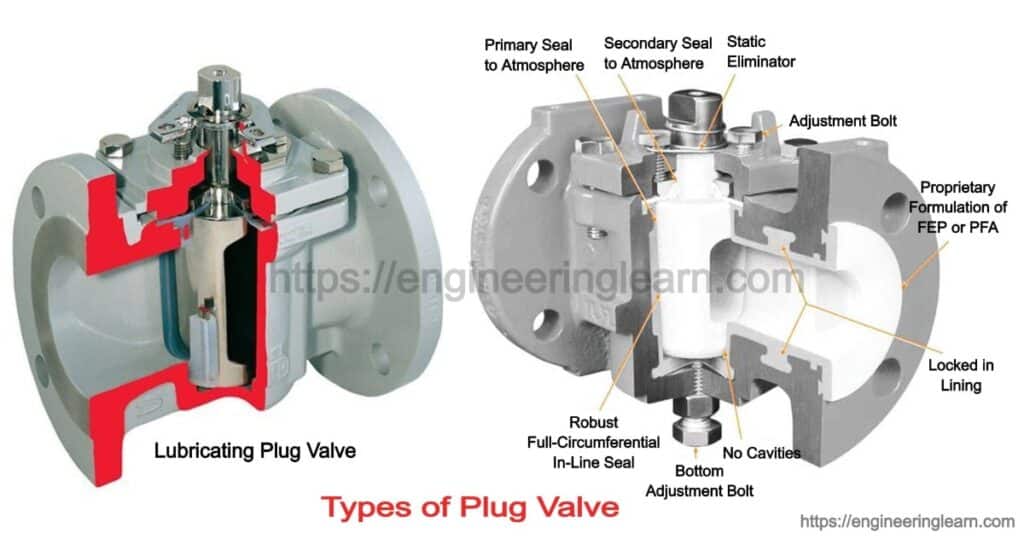

The plug valves are available in two main designs that is lubricated or non-lubricated design and with diverse styles of port apertures through the plug.

1. Lubricated Plug Valve: ( Types of Plug Valve )

The plug within a lubricated plug valve has a hollow space in the middle along its axis. This can be clearly seen in the figure below. The lubricant chamber at the base and the sealant injection fitting at the crest assures the supply of lubricant.

The small check valve beneath the injection fitting averts the sealant from flowing in the reverse direction once the sealant is infused into the hollow space. Plug surface gets continuously lubricated by the sealant that shifts from the Centre hollow space or Centre cavity through radial holes into lubricant grooves on the plug surface. The fine gap around the plug may permit leakage, and if the gap is reduced further, it will enhance the friction and plug may get jammed inside the valve body.

The lubricant lessens the force needed to open or close the valve and permits even or smooth movement of the plug. It also stops corrosion of the plug. The lubricant material must be well suiting the fluid of the pipeline. It should not dissolve or wash away by the flow medium as this could cause pollution in the fluid, and break the seal between the plug and the body, causing a leakage. Also, the sealant used must be able to survive the temperature of the flow medium.

Lubricated plug valves are available in diverse large size range, and they are compatible to work in high-pressure temperature services. These valves are employed to less wear and give better corrosion resistance in some service environments.

2. Non Lubricated Plug Valve: ( Types of Plug Valve )

The non lubricated plug valve employs a non-metallic elastomeric sleeve or liner in it. This sleeve is fitted inside the body cavity of the valve. The polished and narrowed plug functions as a wedge and pushes the sleeve against the body.

This non metallic sleeve decreases the friction between the plug and the valve body. Non-lubricating plug valves are beneficial as they demand minimum maintenance. These valves have non-metallic seat which is why these valves are not generally employed in high-temperature services. Lubricating and non-lubricating valves are competent at providing a bubble-tight shutoff. These valves have an added advantage of their small size.

3. Eccentric Plug Valve: ( Types of Plug Valve )

The design of this plug valve is made such that it employs a half plug. This half plug is beneficial for applications in which a higher seating force with minimal friction from open to closed position is required. The torque seated valves also shows characteristic improved shut off abilities. Eccentric plug valves are widely used for a flow control and isolation uses including clean and polluted water, sewage, sludge and slurries, air, and other services.