Types of Clamps & Their Uses [with Pictures]

Types of Clamps :- A clamp is referred to as a device which is particularly used to hold or secure any object tightly together in order to prevent the movement or separation through the application of inward pressure. The term clamp is commonly used whenever the tool is for temporary use in order to position the components during the construction or woodworking projects.

Different Types of Clamps

There are various types of clamps about which one must know along with its application. So let’s dive in to know more.

1. Hand Clamp: ( Types of Clamps )

Hand Clamps are the tools which are hand operated tools and are used to position or hold the work pieces during an assembly while undergoing any manufacturing process. The key specifications hereby include some intended applications like the clamp type or grip range along with the clamp features.

The Hand clamps are usually available in a very wide variety of styles which includes bar, draw, parallel and toggle which are used for various applications like book binding, picture framing or door making and for certain other manufacturing operations. Clamps are mostly used with laboratory glassware which are also included here as well.

2. Material Handling Clamp: ( Types of Clamps )

Material handling clamps are referred to as those clamping tools which are used to hold heavy material which are usually lifted or manipulated. The key specifications of these types of tools include some of the intended applications like load capacity and the orientation of the clamping action.

These types of clamping tools are used primarily in the construction applications for usually lifting or manipulating large loads. They types of tools are commonly found in use for lifting loads like rails, girders, pipes, etc. and are also used in factories and foundries as well.

3. Mechanical Clamp: ( Types of Clamps )

Mechanical clamps are the devices which are used to hold hoses or tubes in place on the ends of the pipe spuds. The specifications of such clamps include the type of clamp, diameter and material. These devices are also named as hose clamps which are also used wherever a flexible fluid connection needs to be made.

For instant within the water pump of an auto engine and the inlet spud of the radiator. These are made in various sizes and materials which include metal or plastic that depends upon the application which can be designed as single-use or as reusable devices.

4. Pipe Clamp: ( Types of Clamps )

Pipe Clamps are the mechanical devices which are used for hanging or securing pipes. The specifications of such clamps include applications like clamp type and pipe diameter. The pipe clamps are commonly used in piping and plumbing applications for the purpose of hanging various different types of pipes. These clamps can also be for the exhaust pipes, guard rails and conduits amongst all the others. It is amazing to know that there are various styles and sizes in which these devices are available including a variety of materials which depends on the type of pipe that needs to be hung.

The pipe clamp are ideally used for certain jobs which are mentioned below:

- Woodworking

- Welding

- Metal working

- Found having large opening capacity

5. C-Clamp: ( Types of Clamps )

These types of clamps are quite popular and is the standard go-to clamp for various jobs. The best part is that its simplicity and availability are unmatched which means that most of the clamp collection starts with few sizes of C-Clamps. With respect to the popularity of the C-Clamp there are various designs which are available for various types of job requirements.

- Standard C-Clamps one of the most popularly known clamp

- Double Anvil C-Clamps for distribution of even load

- Quick Release C-Clamps for fast action

- Copper Coated C-Clamps uses to prevent weld spatter build up

- Deep Reach C-Clamps used for long reach

These C-clamp are ideally used for certain jobs which are mentioned below:

- Woodworking

- Metalworking

- Low cost

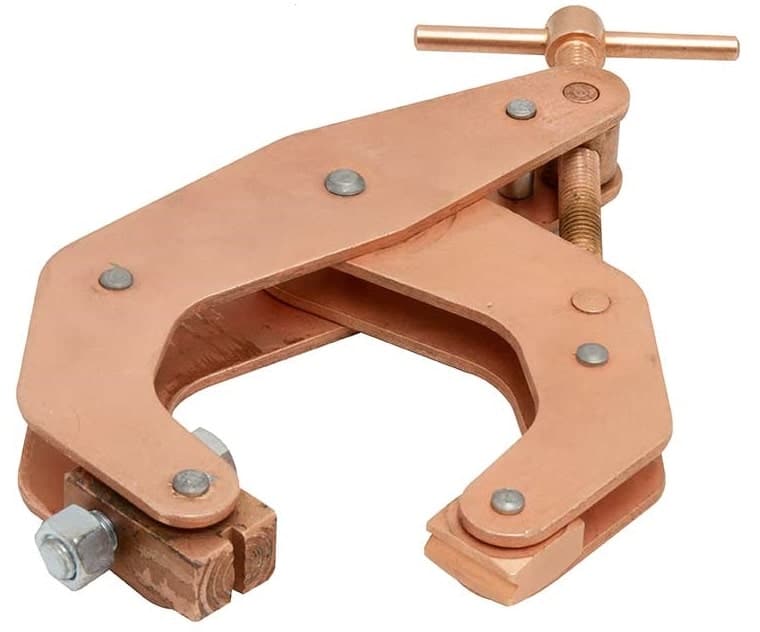

6. Ground Clamp: ( Types of Clamps )

Ground Clamps are referred to as mechanical devices which are used for working for grounding wires, rods, pipes, antennas etc. other than these it is also used for some of the specific tasks like welding and refueling of an aircraft. The specifications of such clamps include the intended application and material. There are various types of ground clamps which are available depending on the construction of the ground wire.

7. F-Clamp: ( Types of Clamps )

The f-clamp are the types of mechanical devices which are designed for a wide opening capacity. These clamps are found having a slider bar which allows the opening capacity which can be easily adjusted in order to satisfy a wide range of applications. This feature of f-clamp has made it very popular clamp and this is the reason why it is used when a C-Clamp’s opening capacity is too small.

These C-clamp are ideally used for certain jobs which are mentioned below:

- Woodworking

- Welding

- Metalworking

- Found having large opening capacity

8. Quick Action Clamps: ( Types of Clamps )

Quick grip or quick action clamps are one of the most popular type of clamps which are used in today’s market. These clamps are used to tighten, using one hand by pumping the push handle. These devices are quite similar to the f-clamps wherein in the clamp opening capacity is found to be varying.

These quick action clamps are ideally used for certain jobs which are mentioned below:

- Speeding the work

- Single Handling

- Woodworking

9. Locking Chain Clamps: ( Types of Clamps )

The locking chain clamp are the mechanical devices which are used for applying a clamp load in tight spaces or around a pipe or near any other surface. The chain is used to clamp a variety of shapes as wraps around the object in order to apply pressure whenever the chain is tightened.

These locking chain clamps are ideally used for certain jobs which are mentioned below:

- Metalworking

- Speeding the work

- One handed

- Varying shapes

10. Sheet Metal Clamps: ( Types of Clamps )

Sheet metal clamps are the clamps which are quite similar to locking clamps. The only difference is that they have a large surface area at the clamp jaws which is responsible for making them ideal for clamping sheet metal and similar materials.

Ideal for:

- Sheet metal

- Metalworking

- Speeding the work

- One handed

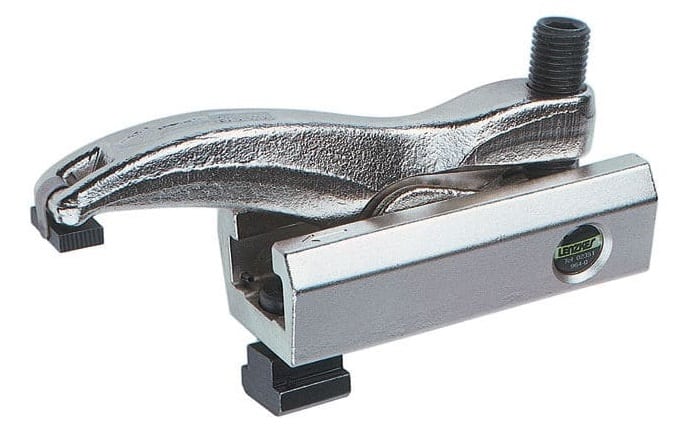

11. Kant-Twist Clamp: ( Types of Clamps )

Kant- twist clamps are favorite clamps of many machine shops and welders as it delivers load by the help of using two parallel jaws and by preventing the jaws from walking. The position of the handle is kept perpendicular with respect to the clamp load which also prevents the clamp from twisting while it is being tightened.