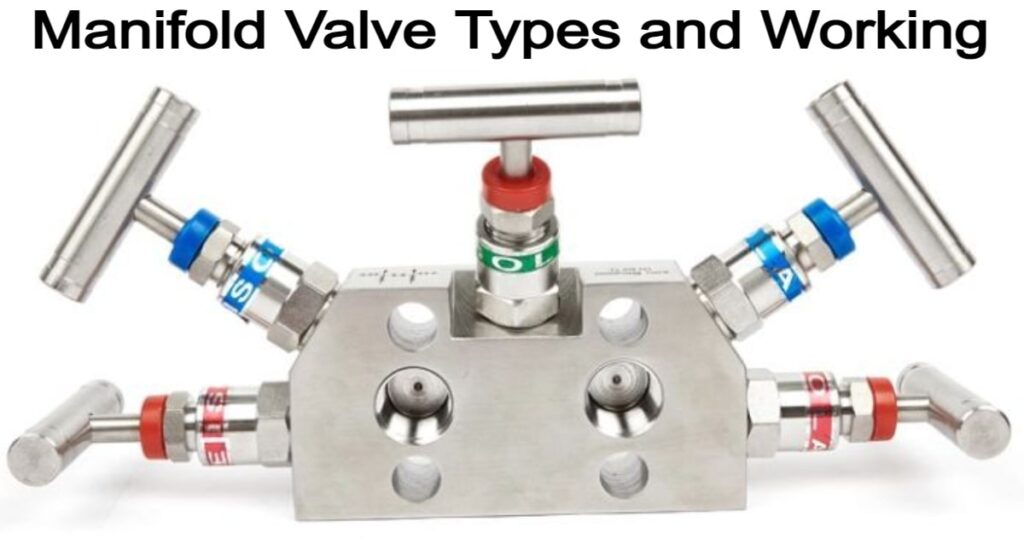

Manifold Valve Types and Working

Figure 1: – Manifold valve with pressure transmitter

General description of manifold valve:

The manifold valve is an instrument which is used to connect the pressure line to the pressure transmitter. The pressure transmitter is a device which measures the pressure of a liquid or gas flowing in a pipeline. The pressure transmitter has a transducer which converts the pressure into analog electrical signal. The manifold is basically a combination numbers of needle valve which takes the input from the pressure line and transfers those pressurized fluid to the pressure transmitter for the measurement.

Types of manifold valves:

There are basically three types of manifold valves used for the purpose; Two way manifold valve, Three way manifold valve and Five way manifold valve.

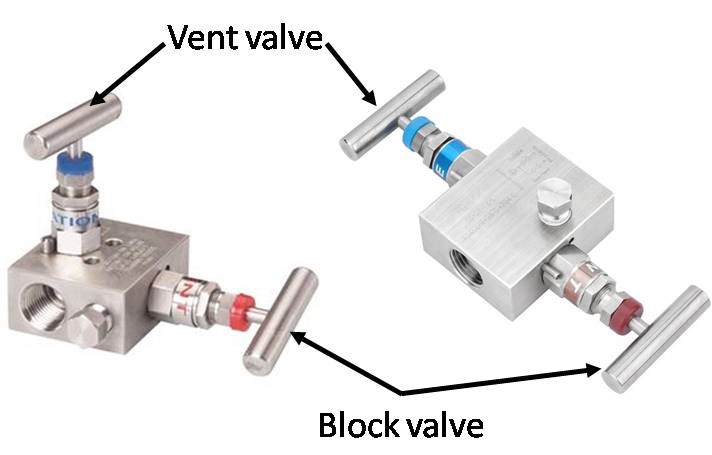

1. Two way manifold valve:

The two way manifold valve has two set of needle valve named as vent valve and block valve, as shown in Figure 2. The block valve is directly connected to the flow line, which takes the input from the pressure line and transferred it to the pressure transmitter. The vent valve is used to vent off the fluid from the flow line if some bubble or inclusion entrapped in the flow line.

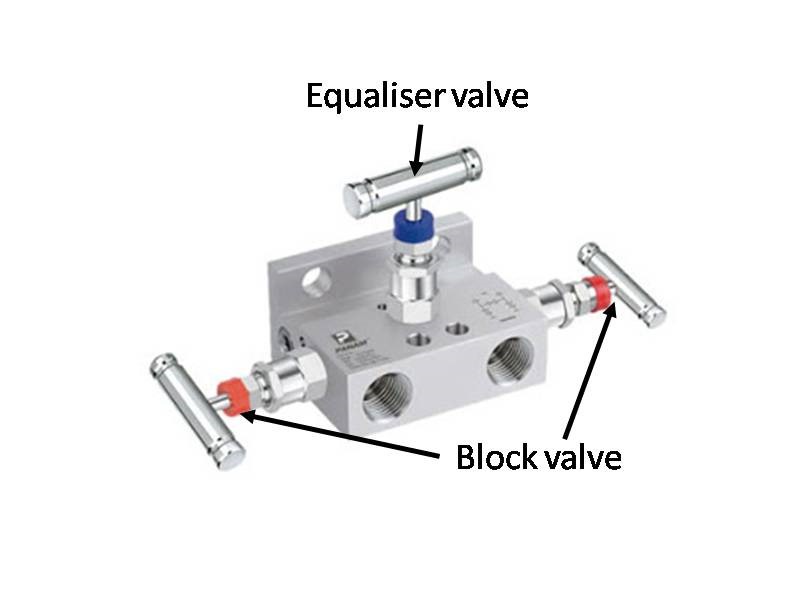

2. Three way manifold valve:

The three way manifold valve consists three needle valves arranged in some manner, such that the two of the valve acts as inlet, named as block valve, and one acts as equalizer valve, as shown in Figure 3. There is no vent valve present in the three way valve. The two block valve is used as input for the high and low pressure accordingly. Whereas, the equalizer valve is used to equalise the pressure of the both high and low pressure input. The equalizer valve is generally used at the time of calibration for the pressure transmitter.

Figure 3: – Three way manifold valve.

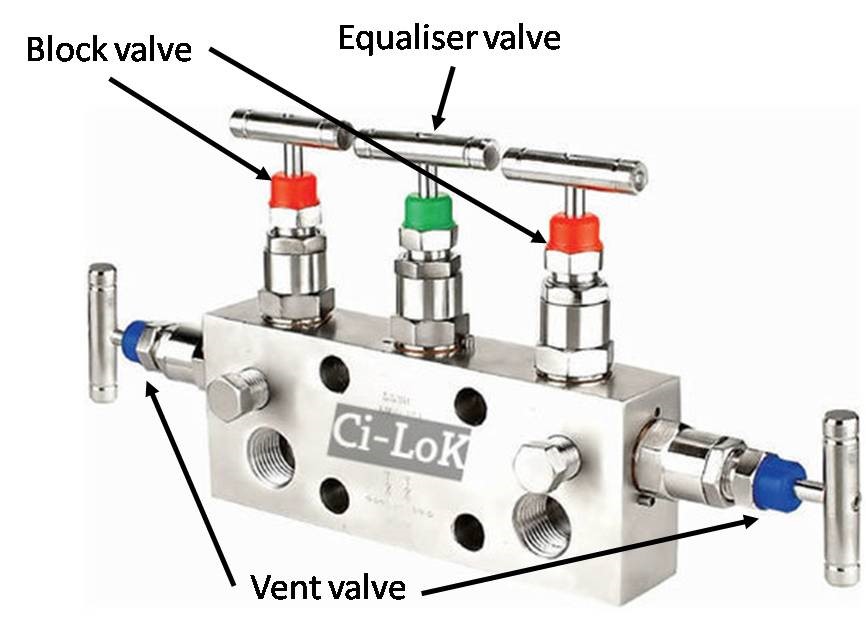

3. Five way manifold valve:

The five way manifold valve consists of five sets of needle valve, in which two are the block valve for high and low pressure input, two are the vent valves for high and low pressure input line and one is the equaliser valve. The functions of vent and equalizer valves are already described in the aforementioned types. The Figure 4 shows the five way manifold valve with the labels for different sub category valves.

Figure 4: – Five way manifold valve.

Working principle of manifold valve:

The manifold valve is made by combining numbers of needle valve for specific purposes. Thus, the working principle of the manifold valve is similar to the needle valve. However, in manifold valve, the input is taken from the high pressure line and transfers it to the pressure transmitter which measures the value of in line pressure. The three way and five way manifold valve is used for the differential pressure measurement, which takes two inputs as low pressure input and high pressure input. There is no such provision is made in the two way valve, as it takes only one input from the pressure line. By rotating the knob of the particular valve, the flow can be regulated in the flow line and thus the measurement of particular pressure line can be done.

Applications of manifold valve:

1. On pressure transmitters, 2-valve collectors generally are used, if the transmitter is isolated and the pressure is disconnected.

2. Three way manifold valves are generally used on differential pressure transmitters, if the process connection has to be blocked or two diaphragms equalized.

3. The five way manifold valves are also used for differential settings and allow two process connections to be blocked, equalized and expelled.