How does 4-Stroke Engine Works

How does 4-Stroke Engine Works :- A four-stroke cycle engine refers to as an internal combustion engine which utilizes all the four distinct piston strokes which include the intake, compression, power, and exhaust in order to complete the whole operating cycle. The piston has two complete passes in the cylinder which is used to complete one operating cycle. The cycle required minimum two revolutions which makes an angle around 720 degree in the crankshaft. A four-stroke cycle engine is one of the most common type of small engine which is found completing five Strokes in a singly operating cycle which includes intake, compression, ignition, power, and exhaust strokes.

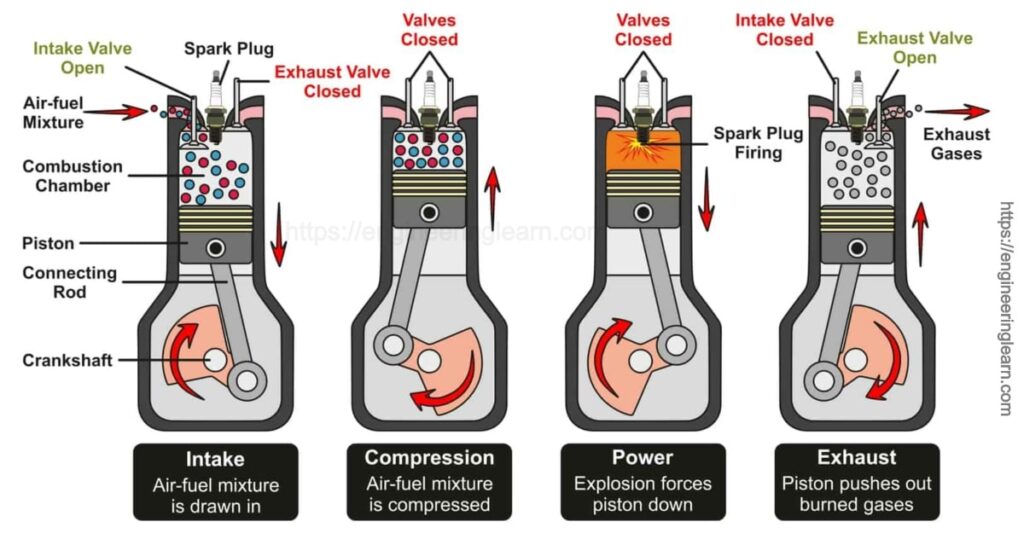

1. Intake Stroke

The intakes required whenever there is a need of air-fuel mixture inside the combustion chamber. This event occurs when the piston shifts from the TDC to BDC and meanwhile the intake valve is kept open. When the piston is moved toward the BDC, it decreases the pressure in the cylinder. The atmospheric pressure proceeds the mixture of the air-fuel into the open intake valve present inside the cylinder in order to fill the low pressure area which is created by the constant movement of the piston.

The cylinder keeps to fill slightly after BDC because the mixture of air-fuel flows continuously due to its own inertia whereas the piston begins to change its direction. The intake valve is kept open at an angle of few degrees of the crankshaft rotation once the BDC is complete which is also dependent on the design of the engine. After this the intake valve gets closes and the air-fuel mixture is sealed completely inside the cylinder.

2. Compression Stroke

The compression stroke is required whenever the air-fuel mixture is trapped and inside the cylinder itself. The combustion chamber is set to seal in order to form higher charge. The charge here refers to as the volume of compressed air-fuel mixture which is trapped inside the combustion chamber and is kept ready for ignition.

The process of compressing the air-fuel mixture is done to help in releasing more energy whenever the charge is ignited. Both the intake as well as exhaust valves must be closed to make sure that the cylinder is sealed which shall only provide high compression. It is a process by which either reducing or squeezing a charge is done from an increased volume to a decreased one inside the combustion chamber. The flywheel helps to maintain the necessary momentum in order to compress the charge. If the piston of an engine is found to compress the charge then an increase in the compressive force is applied by the piston which is responsible to cause heat which is generated.

How does 4-Stroke Engine Works

There also occurs an increase in fuel vaporization in terms of small droplets which get vaporized more quickly with respect to the heat which is generated. The droplets increase the surface area of the exposed ignition flame and helps in completely burning the charge inside the combustion chamber. It is only gasoline which ignites in the form of vapor. If the droplet surface area of the gasoline is increased, then there could be more release of vapor instead of the remaining a liquid.

It should be noted that as much as the charged vapour molecules are compressed, more and more amount of energy will be obtained from the process of combustion. The energy which is needed to compress the charge is quite less than the force which is gained in or produced during the process of combustion. The ratio of compression of an engine is the volume of the combustion chamber within the piston at BDC to the volume of the combustion chamber within the piston at TDC.

This area is combined with the design and style of a combustion chamber which is responsible for determining the ratio of compression. The fuel efficiency of the engine depends upon the higher compression ratio. The higher compression ratio usually provides an increase in the combustion pressure or force on the piston. Whereas, higher compression ratio increases the effect of the operator which is required to start the engine.

3. Power Stroke

The power stroke refers to as an engine operation stroke in which the hot forces of the gases expand the head of the piston away from the head of the cylinder. The force of the piston and its motion is transferred through the connecting rod in order to apply the torque to the crankshaft which is applied to initiate the rotating movement in the crankshaft. The torque which is produced is determined by the amount of pressure calculated on the piston, its size, and the throw of the engine. Both the valves are kept closed during the power stroke.

4. Exhaust Stroke

The exhaust stroke can refer to in that case wherein the spent gases are expelled from the combustion chamber and are released directly into the atmosphere. This is thus the final stroke which occurs when the exhaust valve is kept open whereas the intake valve is kept closed. The movement of the piston removes the exhaust gases into the atmosphere.

Once the piston reaches the BDC during the power stroke, the combustion is completed and the cylinder is filled with the exhaust gases. Then the exhaust valve is opened and inertia of the flywheel pushes the piston and the moving parts back to TDC which pushes the exhaust gases out from the exhaust valve which is kept open.

Ignition Event

The ignition event is also referred as a combustion event which happens when the charge is ignited and oxidized rapidly with the help of a chemical reaction which intends to release heat energy. Combustion refers to a rapid oxidizing reaction which combines with the fuel chemically in the presence of oxygen in the atmosphere and in turn releases energy in the form of heat.

Combustion event involves a finite time which is taken to spread a flame within the combustion chamber. The spark is initiated with the help of a spark plug at 20° before the crankshaft rotation.