Chemical Throttle Valve (CTV): Definition, Working, Features & Needs

What is Chemical Throttle Valve?

Chemical Injection Throttle Valve ( CTV): Definition, Working, Features & Needs :- Throttle is a mechanism which controls the fluid flow by controlling the opening of the fluid line. The less will be the passage area the more the fluid will be throttled. The chemical throttle valve (CTV) is generally used to control the flow rate and amount of chemicals such as scales, wax and corrosion inhibitors at the sub-sea zone.

Working of Chemical Throttle Valve (CTV)

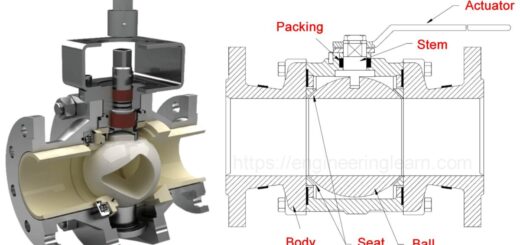

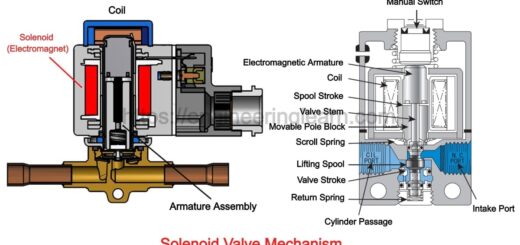

A CTV consists of features of a flowmeter, actuator, controller and a valve. These all systems incorporated together and on the basis of a physical property, it automatically discharges the chemical into the pipeline. The physical properties may be viscosity, pressure differential, specific gravity and temperature or other thermodynamic properties. Amongst all these properties the thermodynamic properties of metal such as expansion on heating and contraction on cooling are considered best because of its effective and accurate sensitivity and resolution. ( Types of Valves )

In general condition, the valve remains closed. A timer is set in the CTV which switch on and off the heater attached with the valve. As the heater gets on, it heats the outer shell of the valve, which expands by taking up the heat. The expansion of outer shell causes opening of the passage and the chemical starts flowing in the channel. As the heater shuts off the outer shell of valve loses heat and hence gets contracted to close the passage. In addition, the thermal flow measurement system is also equipped in the CTV, shown as T1 and T2 in the figure. The difference in temperature between the output and input shows the flow rate inside.

Need for Chemical Throttle Valve (CTV)

Chemical injection is an essential process for the upstream sector of the gas and oil industry. Various substances found in petroleum adheres to the inner walls of pipelines found at oil wells, leading to scaling and corrosion. To prevent these issues chemical injection becomes an important process. The conventional equipment for chemical injection is multi head dosing pumps and manually controlled flow rate using pump and valve. But these conventional processes of chemical injection do not give proper control over the flow and amount of chemicals into the oil wells, which subsequently leads to unnecessary cost of chemicals due to overdosing, frequent maintenance and increase of labor cost, damaged assets caused by under dosing etc.

In order to solve these issues an automatic system is needed which not only control the flow of chemicals but also meters them. The CTV served for that purpose.