Carburetor Types

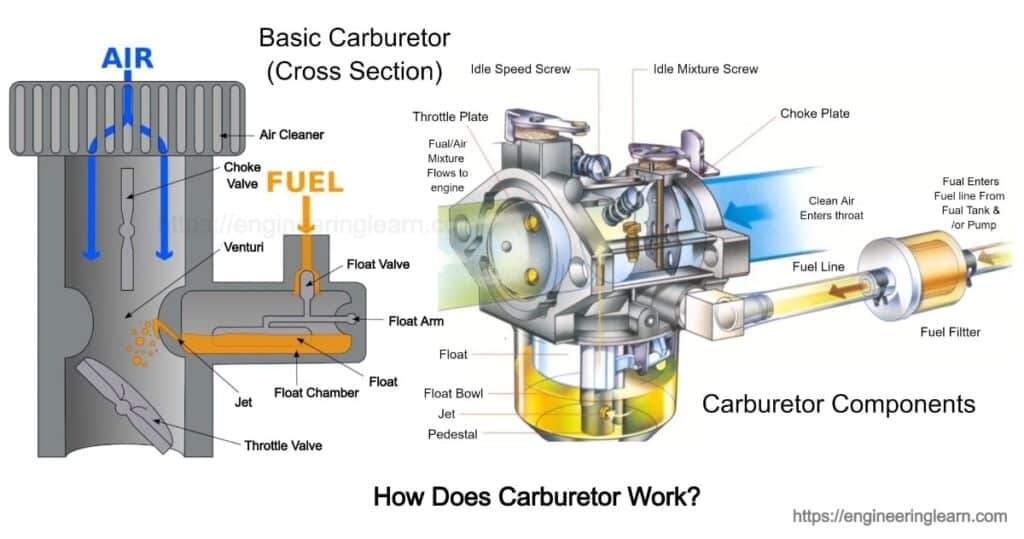

Carburetor Types :- It is a mechanical device used to supply air-fuel mixture in an S.I. (spark ignition) engine. This process is known as carburetion. It mixes the air and fuel in proper manner to make charge which is to be delivered to the combustion chamber.

Need of Carburetor?

As we know that the proportion of air and fuel in the charge is dependent on the engine parameters viz. speed, load. It varies with different conditions. To fulfil this requirement of changing and regulate the air fuel ratio depending upon the condition carburetor is used.

Carburetor Working Principle

Carburetor works on the Bernoulli’s principle. At the time of suction stroke Air is drawn inside the cylinder using a Venturi. As the speed of air passes through Venturi increases it creates less pressure inside the Venturi and creates a pressure difference between venturi and float chamber (a kind of fuel reservoir). This pressure difference draws the fuel inside venturi from float chamber. Higher the air velocity higher the fuel content and vice versa. The speed of air in venturi is maintained according to the speed of vehicle. Thus simple carburetor helps to regulate the air fuel ratio in IC engine.

Carburetor Types

A. On the basis Direction of flow of air

- Up-draft type carburetor

- Down-draft type carburetor

- Horizontal type carburetor

1. Up-draft type Carburetor

In this type of carburetor, air enters through the bottom side of the carburetor and fuel is supplied from the float chamber. Due to the pressure difference within the Venturi and float chamber, fuel comes out from the fuel pipe located inside the venturi. It mixes with the inlet air and makes a mixture of air-fuel, which discharges through the throttle valve which is regulated by the accelerator.

2. Down-draft type Carburetor

In this type of carburetor air enters from the top of the carburetor, and the fuel comes from the float chamber. Just like in previous case, here also the same principle works, due to pressure difference between venturi and float chamber fuel comes out through the fuel pipe and then it mixes with air.

The ratio of mixture of fuel and air is governed by the choke valve and the amount of charge supplied to the combustion chamber is governed by the throttling valve.

Today most vehicles used down-draft carburetor systems because of the following advantages

• Gravity helps in the flow air and fuel.

• Higher volumetric efficiency.

3. Horizontal type Carburetor

It is also known as cross-draught carburetor. In this type, the carburetor stays in the horizontal position and the air enters through the one end of the carburetor. The fuel pipe remains in the vertical position as in previous case such that they both are at right angles. The working principle is same as the up draught or the downdraught carburetor. That is, due to pressure difference, fuel in sucked inside Venturi and regulated by air velocity. This air fuel mixture is supplied to the combustion chamber through another end of carburetor.

B. On the basis of Method of fuel Regulation

- Constant vacuum carburetor

- Constant choke carburetor

- Multiple Venturi carburetor

1. Constant vacuum Carburetor

It is also known as variable choke carburetor. In this type of carburetor air and fuel flow areas are varied depending on the demand of engine while the pressure difference is kept constant. The S.U. and Carter carburetor are good examples of constant vacuum carburetor.

2. Constant choke Carburetor

In constant choke carburetor flow areas of air and fuel are kept constant while the pressure difference between venturi and float chamber is varied depending on the demand of engine. The Zenith carburetor and the Solex carburetor are good examples of constant choke carburetors.

3. Multiple Venturi Carburetor

It is also known as multiple-barrel. In this type of carburetor one or more secondary venturi are concentrically enclosed inside the primary venturi of carburetor. The secondary venturi works as boost Venturi. It is located at the upstream of the primary venturi. Its positon is such that the discharge end is located at the throat of primary venturi . The pressure at the exit of boost venturi is same as the throat pressure of primary venturi.

Advantages of Multiple Venturi System

• Can work under high velocity ~200m/s.

• Works better at low speeds too.

• Good air-fuel mixing is achieved without significant loss in volumetric efficiency.

C. Automobile Carburetor

There are mainly three types of carburetor used in automobiles

- Solex carburetor

- S.U. carburetor

- Carter carburetor

1. Solex Carburetor

It is a modification of simple carburetor. It is designed to overcome the drawbacks of simple carburetor. The simple carburetor works well in normal conditions but its efficiency lowers in winter and summers when the temperatures are at extreme. In above mentioned conditions, Solex carburetor works well. It is a downdraught type carburetor. Solex Carburetor provides the rich mixture at the time of starting of engine and provides a lean mixture when travelling in economical speed with the vehicle.

2. S.U. Carburetor

S.U. carburetors are completely different from other carburetors. It is a constant vacuum or a constant depression type of carburetor with an automatic variable choke. The air-fuel ratio in the S.U. carburetor is regulated by the movement of piston cylinder arrangement.

The main parts of SU carburetor are helical spring, piston, piston rod, suction disc, suction chamber, jet, jet needle, throttle valve. Pressure in the suction chamber inside cylinder is directly proportional to the state of a butterfly type throttle valve while the pressure at suction disc is atmospheric.

3. Carter Carburetor

It is a down-draught type carburetor.

In the carter carburetor the fuel enters into the chamber and air enters from top via the choke valve. The choke valve stays open during the normal running conditions of the engine.

In Carter carburetor three venturies (Primary, secondary and third main venturi) are present. Among the three, primary venturi is the smallest venturi located above the fuel level in the float chamber. Secondary venture and third main venturi are located below the primary venturi. Depression present at the primary venturi is used at low engine speed. Fuel from the float chamber comes into the primary venturi using fuel pipe directing upwards. This mixture of air and fuel then goes from primary to the third venturi through secondary venturi. From the third venturi it is supplied to the combustion chamber.

Carter carburettor helps in smooth running of engine as fuel reaches the combustion chamber through the multiple venturies and fuel gets atomized.