Types of Piston

What Is A Piston?

Types of Piston (What is piston) :- A piston is a component of I.C. engine; it is shaped like a disk which reciprocates inside the cylinder. The piston moves due to combustion of fuel-air mixture in the cylinder. The piston also does the work of compressing the fuel air mixture.

The main work of piston in any internal combustion engine is to receive the impulse which is generated due to the expansion of the gas. Then this impulse is transferred to the connect shaft via the connecting rods. Another main purpose of the piston is to dissipate the excessive heat produced due to combustion to the engine cylinder walls.

Types of Piston

We classify piston on the basis of following factors-

A. This classification is based upon the Skirt Design.

Types of piston according to this classification are-

1. Solid Skirt Type Piston: ( Types of Piston )

This piston has no cutting on it. Neither it has any symbols or names engraved on its skirt. This type of piston is generally used in diesel engines in which more power is generated. So it is used where there is more thrust or load acting on the engine.

2. Split Skirt Type Piston: ( Types of Piston )

In split skirt piston the piston skirt is splitted into two parts. This type of piston is generally used in two stroke engines, petrol engines or small engines. It was used in olden times and it is less used in the modern times.

3. Slotted Piston or Constant Clearance Piston

- This type of piston is just like an ordinary piston but it has slot cut on it. If the slot is of T shape then it is called ‘T’ slotted piston and if it is of ‘L’ shape then it is called ‘L’ slotted piston.

- ‘T’ Slotted piston

- ‘L’ Slotted piston

B. This classification is based on the Shape and Application of Piston

We classify piston on the basis of following factors-

1. Slipper Type Piston: ( Types of Piston )

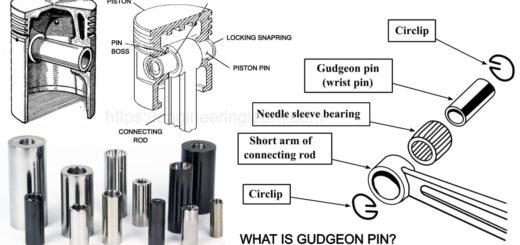

This type of piston is used in modern day high speed engines. It is just like normal pistons but the only difference is that its inertia weight (inertia weight is the piston’s weight only) is more. In this one side of the piston is attached with the gudgeon pin and it is fixed on that side while on the other side piston undergoes movement on both sides. The side of piston with the gudgeon pin is called non-thrust.That side is free from any jerks and it remains fixed. Whereas the other side is known as thrust side.

The skirt on the thrust side acts as a guide whenever the piston performs up-down movement. When the piston goes to TDC, it hits the wall lining on the left side and when it comes down it hits the wall lining on the right side. Whenever there is a thrust, a sound is produced which is called “piston snap”. Hence the piston diameter is more at the thrust side (at the side of skirt). To reduce the weight of the piston a portion of metal is cut from the piston.

2. Steel Inserted Type Piston: ( Types of Piston )

This type of piston is used in heavy or big engines. During the power generation in the engine, thrust acts on the piston boss. In case more power is generated then there is more chance of damage on the piston boss. Hence to reduce the damage and to increase the area of contact, a steel sleeve is inserted in the piston (piston is made up of aluminum alloy).

3. Steel Belt Type Piston: ( Types of Piston )

In this type of piston a steel belt is provided in the piston in between piston boss and ring land. This belt stops the piston to expand when the piston gets heated.

4. Cam Ground Type Piston: ( Types of Piston )

The bottom part of the piston is not circular but of oval shape, that is, the diameter of the thrust side is more and the diameter of the non thrust side is less. This is used in modern day engines.

5. Alfinz Type Piston: ( Types of Piston )

In this type of piston, a steel alloy is fixed in the grooves of the ring. The design of it resembles that of a hook.

6. Heat Dam Type Piston: ( Types of Piston )

Generally three ring grooves are cut on a piston, but in this piston an additional groove of less depth and less width is cut above the ring grooves. The main advantage of using the heat dam piston is to stop the flow of heat (which is produced from the blast of air-fuel mixture inside the engine) from the top of the piston to the bottom of the piston. If the heat flows from top to the bottom of the piston than the piston can get struck in the liner. Hence to avoid this, heat dam pistons are used.

C. This classification is based upon the design of head or crown of the piston

We classify piston on the basis of following factors-

1. Dome Type Piston: ( Types of Piston )

The head of this type of piston has a dome shape resembling the top of a stadium. Additional volume is added to the top of the piston by giving it a dome shape. This increases the compression ratio and hence increases the overall performance.

2. Concave Type Piston: ( Types of Piston )

The piston is generally shaped concave beforehand only because after the application of gas pressure on the crown of the flat piston , it takes an unsymmetrical concave shape. This result in fatigue on piston and the piston may fail. Hence pistons are already made in concave shape in order to distribute the gas pressure symmetrically.

3. Irregular head Type Piston: ( Types of Piston )

The purpose behind giving the irregular crown shape is to create turbulence to get the proper air- fuel ratio.

4. Flat piston Type Piston: ( Types of Piston )

This type of piston has a flat top.

Image Source :- Erautotechwithab, Jepistons, Kindpng, Fastnlow, Dlpng