Flywheel Types & Function

Flywheel Types & Function :- Flywheel is rotating body which is quite heavy and performs like the source of energy. It acts as a medium of whole energy accumulates b/w energy source and machinery. Energy present in the flywheel is in the form of kinetic energy. Flywheel & governor most probably used in an power plant ( i.e, I.C Engine) or reciprocating pumps or compressor.

Function of flywheel

- It is used to accumulate energy & supply whenever further required during operation.

- For reduction in speed stability(fluctuation).

- To reduce the power capacity of electrically fired motor or engines.

Flywheel don’t have control over the supply of fuel. Flywheel doesn’t used to maintain constant speed ( used for prevent fluctuation of energy in the process system). Flywheel uses inertia to run machine at the dead center.

Flywheel relatively have high inertial force and heavy part of system. The operation of flywheel is continuous from cycle to cycle. It control the speed in single time.

Material of construction

Flywheel is generally made up of cast iron having following advantages described below:

- Cast iron flywheel are the cheapest.

- C.I flywheel can be given or changed to any shape without involving any machining operation.

- Fair ability to damp vibration.

Governor

Governor is the member of machine used to maintain the constant speed.

Functions of governor

it is used to regulate the fuel supply according to load requirement & runs machine at the constant speed irrespective of output required. Operation of the governor is intermittent. Speed control over a period of time. Governor is used in engines or turbines.

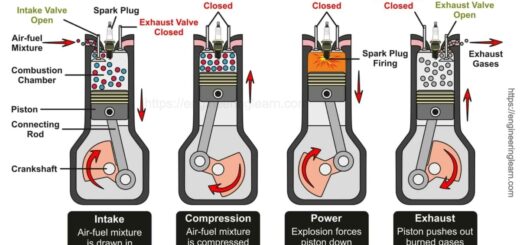

Process inside of I.C engine

mainly this process consist of 4 procedure are described below:

- Suction strokes.

- Compression strokes.

- Expansion (power) strokes.

- Exhaust strokes.

There is only process where power is produced by the engine that process is called the expansion

(Power)stroke. In all three remaining process the energy is provided by the engine.

Application of flywheel

- It can be used in internal combustion engine, stem engine.

- Balancing of reciprocating pumps & compressor.

- In punching presses & sewing machine.

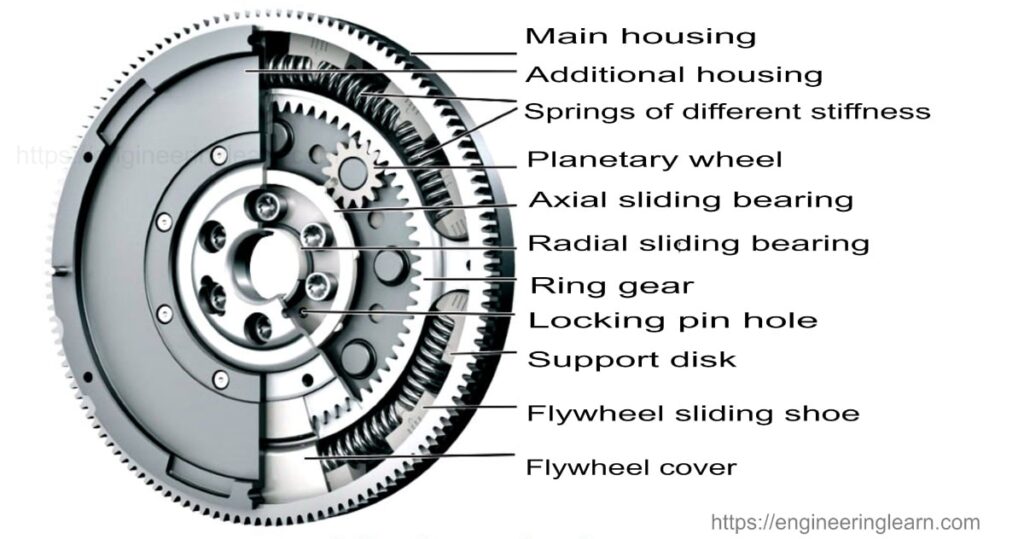

Types of flywheel

- Solid disk flywheel

- Rimmed flywheel

1. Solid disk flywheel

It is basically a solid circular disk.

Whereas Mass moment of inertia for the solid circular disk flywheel is:

I= (m. Square of radius/2) (eq . A)

Where I = mass moment of inertia of the disk (kg per meter square).

m = mass of the disk (kg)

R = outer radius of the disk (m)

While mass of the disk is given by

m = 3.14X square of radius X thickness X density (eq. B)

Density = mass density of flywheel material.

From eq A & B

I = (3.14/2) X density X thickness X radius raise to the power 4

There are two principle stresses used in the flywheel are

- Tangential or radial stress.

2. Rimmed flywheel

- components of rimmed flywheel are Rim ( outer ring), hub (inner hub), arms ( 4-6).

Stress involved in the rimmed flywheel is tensile stress due to centrifugal force acting on the rims.

Mass moment of inertia for the rimmed flywheel is given by:

I ( Subscript r ) = C X I

Where,

Ir = moment of inertia of rim about it axis of rotation.

C= factor for mass moment of inertia ( varying the value from 0.9 – 1.0 )

I= mass moment of the inertia of entire rimmed flywheel.