Thermostatic Expansion Valve Working and Types

Thermostatic Expansion Valve

A thermal expansion valve or thermostatic expansion valve is a device which controls the amount of refrigerant released into the evaporator and is intended to maintain a steady value of the superheat of the refrigerant that flows out of the evaporator. It is often abbreviated as TEV, TXV, or TX valve) is an important component in vapour-compression refrigeration and air conditioning systems. This device isn’t able to regulate the evaporator’s temperature to a precise value, although often described as a “thermostatic” valve. The evaporator’s temperature is dependent on the evaporating pressure, which is regulated through other means (such as by adjusting the compressor’s capacity). The regulation of superheat is achieved with the help of a membrane present in the valve housing. The usage of this expansion device is most common in BHPE (Brazed Plate Heat Exchanger) evaporators.

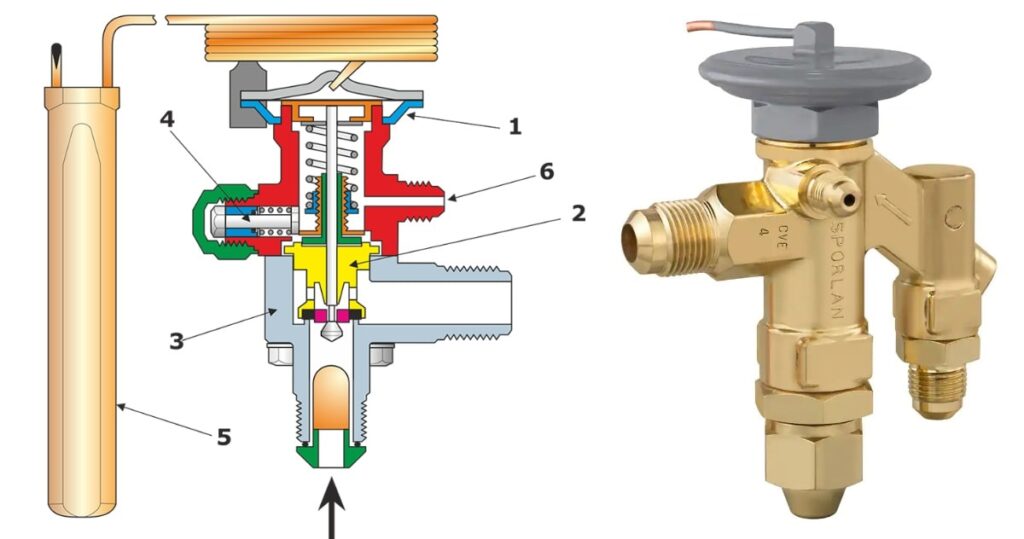

Construction

1. Metallic diaphragm:

This is a flexible metallic plate that can expand because of the pressure of refrigerant inside the refrigeration or air conditioning plant.

2. Power element:

Powerelement is the upper portion of the thermostatic expansion valve which is filled with gas. In the case of the air conditioning system, the gas filled in element is the same as the gas filled in the air conditioning system, i.e. the refrigerant gas. For example, if the air conditioning system has R22 refrigerant, the gas filled in the power element is also R22. The power element and the feeler bulb are connected to each other through a thin tube or capillary tube and the same gas is filled in the tubing and the feeler bulb. Thus the feeler bulb, the connecting tubing and the power element, together form a single flexible chamber. The feeler bulb is also connected to the evaporator and thus it senses the temperature inside the evaporator of the refrigeration system. The volume of the gas inside the power element changes according to the temperature sensed by the feeler bulb inside the evaporator. If the temperature inside the evaporator is high then gas in the feeler bulb will expand and thus the gas in the power element will also expand and its pressure will increase. The expanded gas pressure inside the power element tends to open the thermostatic expansion valve. There are three different types of feeler bulbs used in thermostatic expansion valves :

- Liquid-charged bulbs: Filled with a large quantity of refrigerant, and contains the refrigerant in both liquid and gas state.

- MOP (Maximum Operating Pressure) bulbs – also called gas-charged bulbs: They are also known as gas charged bulbs and are filled with a very less quantity of refrigerant.

- Adsorption-filled bulbs

3. Valve seat and needle:

In the, the lower side of the thermostatic expansion valve, the valve seat and the needle are located. The metallic plate that provides passage for the flow of the refrigerant is called the valve seat. The needle on the other hand, is connected to the lower part of the diaphragm. The needle moves inside the opening of the valve seat. Due to high pressure inside the power element, the diaphragm moves down and thus the needle moves down as well, thereby opening the thermostatic expansion valve. When the needle moves up, the valve closes along with. An orifice is formed by the valve seat and the needle. This orifice allows the flow of refrigerant through it.

4. Spring:

The thermostatic expansion valve has a spring, located at the bottom of it. Under normal conditions, or say by default, the spring is compressed, and tends to move the needle of the valve in an upward direction in order to close the valve. Depending upon the degree of superheat in the evaporator, the pressure of the spring is adjusted by the manufacturer. The thermostatic expansion valve bought should be of required spring pressure. The spring is also fitted with a screw to adjust the spring pressure, but it’s generally not advisable to use it.

5. Liquid Inlet Port and Outlet to Evaporator:

Thermostatic expansion valve has tubing coming from the condenser. Liquid inlet port is connected to that tubing. It is through this port that the refrigerant enters the thermostatic expansion valve. There is an outlet leading to the evaporator. The refrigerant passes through the orifice of the valve seat and the needle and then enters the evaporator in a flashed condition.

Working of Thermostatic Expansion Valve:

As already mentioned earlier, the aim of this device is to maintain a stable superheat in the evaporator. It does so by adjusting the mass flow rate of the refrigerant.

So as we have seen above, there’s a feeler bulb. The reason behind this name is that it is used to sense or feel the temperature of the evaporator. This bulb has two connections. It is connected to the output of the evaporator thermally. And it is also connected to the power element through a capillary tube. It is already mentioned that the bulb and the power element are filled with the refrigerant. But it can also be filled with some other fluid having the same thermodynamic property as the refrigerant. When there is a rise in temperature of the refrigerant in the evaporator, the fluid in the bulb and eventually the fluid in the power element expands. Thus the diaphragm (also referred to as membrane in some places) experiences a downward pressure against the spring and the needle moves downwards allowing the refrigerant to flow through the orifice. When the mass flow rate of refrigerant increases, the temperature in the outlet of the evaporator decreases too as now there will be more heat required for superheat. Thus some of the fluid in the bulb condenses, decreasing the pressure on the diaphragm. Thus the spring pushes against it and the needle moves upwards, decreasing the mass flow rate of refrigerant. Thus, eventually a balance is achieved.

Types of Thermostatic Expansion Valve:

Classification of thermal expansion valves is done of the basis of how the evaporator pressure affects the position of the needle, which controls the flow of the refrigerant. Thus they are of two types: internally equalised and externally equalised.

i) Internally equalised:

In these valves, the pressure in the inlet of the evaporator is used internally to exert pressure on the diaphragm upward and thus close the valve, restricting the flow of refrigerant and equalising the pressure. This is ensured through an internal connection between the two. For these valves, there will be an increase in the superheat if the pressure in the evaporator drops. Single circuit evaporator coils use these kinds of valves. In general they are used in the applications where the pressure drop is low.

ii) Externally equalised:

In these types of valves, the pressure at the outlet of the evaporator is used to exert an upward pressure on the diaphragm in order to close the valve, using an external equaliser tube. This type of valve is used for the applications in which a high pressure drop is involved.

Note: These two kinds of thermostatic expansion valves can’t substitute each other in their respective applications and can affect the system adversely, if interchanged. For example, if internally equalised valve is used in a high pressure drop system, it starves the coil. Thus proper type of valve should be selected.

The external equalised port of a thermostatic expansion valve should never be capped.

Besides this, thermostatic expansion valves can also be divided into two types on the basis of how they sense the temperature of refrigerant in the evaporator and regulate the flow. The two types are:

(A) Bulb/diaphragm type:

As the name says, it uses a bulb to sense the temperature of the refrigerant, and the diaphragm is used to push against the spring, moving the needle downward and increasing the refrigerant flow. They are used in most systems where the refrigerant superheat is required to be controlled.

(B) Electronic expansion valve:

In this type of valve, temperature and pressure sensors are used. It uses a stepper motor sealed inside the valve. This motor controls the motion of the needle using a screw mechanism and actuates the required motion as per the data from the sensors. These valves are used in the larger systems or the systems with multiple evaporators.

Electronic expansion valves offer greater control range and flexibility as compared to the bulb/diaphragm valve. But, they also increase the complexity of the system and increase the risk of failure due to usage of multiple sensors and an electronic circuit.